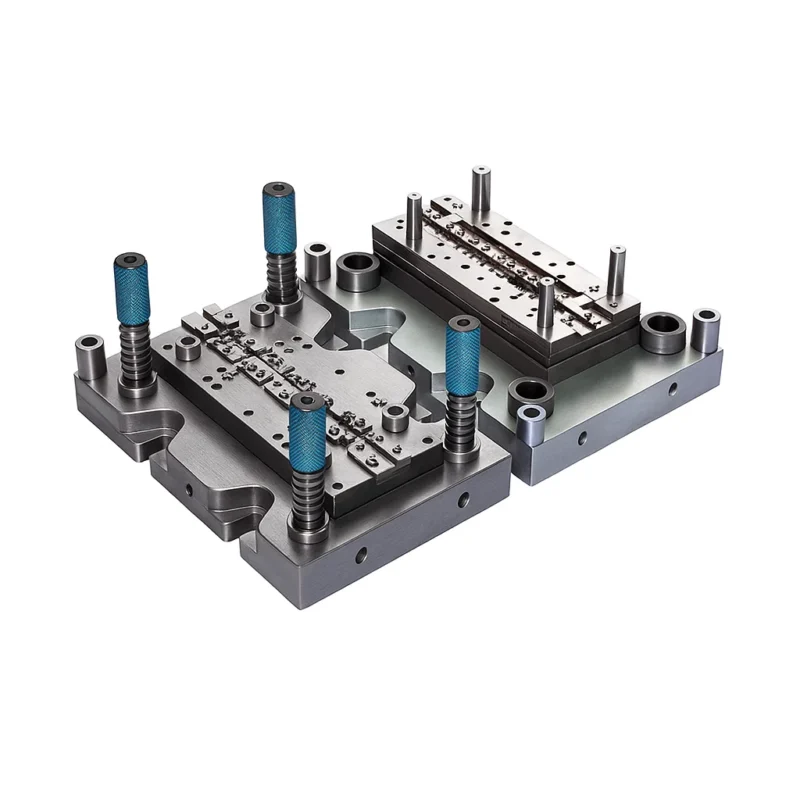

We provide comprehensive technical and engineering services tailored to the manufacturing needs of multiple industries, with a strong focus on plastic injection molds, silicone rubber molds, and liquid silicone rubber (LSR) injection molds. Our capabilities allow us to deliver high-quality products to customers across a broad range of sectors, including automotive, lighting, медыцынскі, agricultural, and avionics applications.

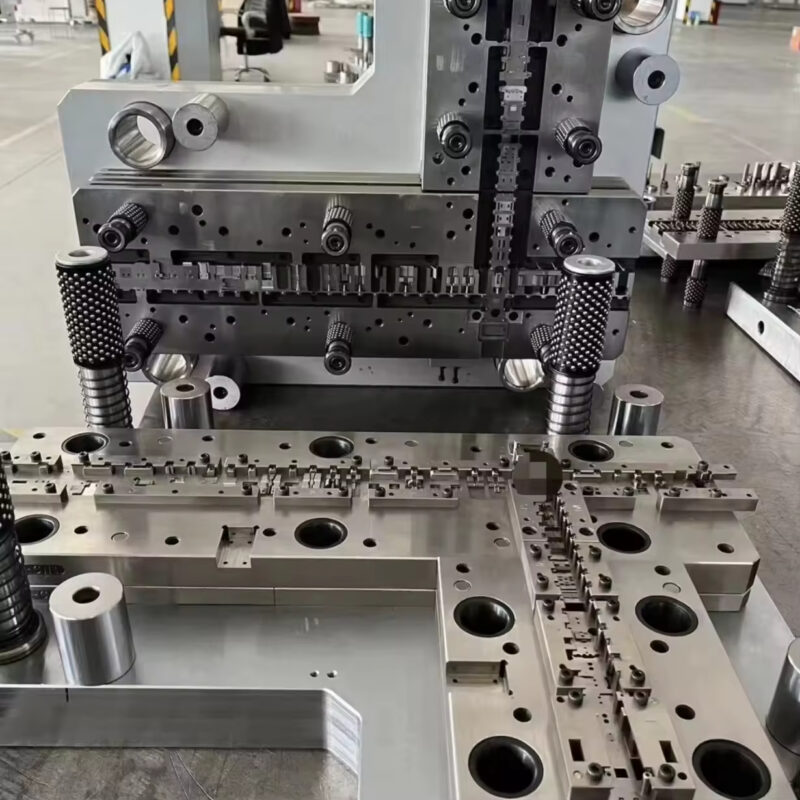

Mold Processing Center

Qianwei’s mold processing center is equipped with a full suite of advanced CNC machinery, including CNC wire-cutting machines, CNC internal grinding machines, and both 2D and 3D coordinate measuring systems. These high-performance machines are sourced from leading manufacturers in Germany, Switzerland, Japan, and the United States, ensuring excellent reliability, stability, precision, and overall performance.

Our facility is supported by a team of more than 50 skilled technicians and engineers. To further improve operational efficiency, we operate 12 fully integrated automatic storage and retrieval systems (AS/RS). This advanced setup allows us to effectively manage an inventory of over 4,000 molds, along with more than 30,000 inventory items and finished products.

У Qianwei Precision, we utilize a wide range of industry-standard software tools, including AutoCAD, Pro/ENGINEER, Unigraphics, and ABAQUS. These CAD/CAM and product lifecycle management systems play a critical role in enhancing design accuracy, optimizing manufacturing processes, and supporting product development throughout the entire lifecycle.

With nearly 15 years of experience in mold design and development, Qianwei has built deep technical expertise and a strong track record. Our portfolio includes approximately 30,000 products and more than 4,000 mold sets. Whether you need support refining existing designs or collaborating on new product development, Qianwei is a trusted engineering and manufacturing partner you can rely on.