In the world of modern electronics, reliability is everything. Whether it’s a smartphone, an electric vehicle, or an industrial control system, the performance of each device depends on the quality of its electrical connections. That’s where precision machining comes in.

Precision machining technology ensures that every connector component—from pins to housings—is produced with extreme accuracy. This not only enhances performance but also guarantees long-term stability in demanding environments. In this article, we’ll explore how precision machining improves connector reliability and why it’s the foundation of modern connector manufacturing.

Understanding Precision Machining in Connector Manufacturing

What Is Precision Machining?

Precision machining is a manufacturing process that uses advanced computer-controlled tools to create highly accurate metal and plastic parts. For electronic connectors, this process is essential to achieve the tight tolerances and consistent quality required for reliable signal transmission.

Common precision machining technologies include:

- CNC (Computer Numerical Control) machining

- Wire EDM (Electrical Discharge Machining)

- Micro stamping

- Injection molding

Each of these processes plays a unique role in ensuring that every connector component meets exact specifications.

Why Precision Matters for Connectors

In connector manufacturing, even a small deviation—just a few micrometers—can lead to poor contact, unstable signals, or mechanical failure. Precision machining eliminates these risks by producing parts that fit perfectly together.

Reliable connectors:

- Maintain stable electrical conductivity

- Prevent intermittent signal loss

- Reduce the risk of mechanical wear or corrosion

- Provide longer operational life

For high-performance applications like 5G communication, automotive electronics, or aerospace systems, precision is not optional—it’s essential.

Key Precision Machining Techniques for Connectors

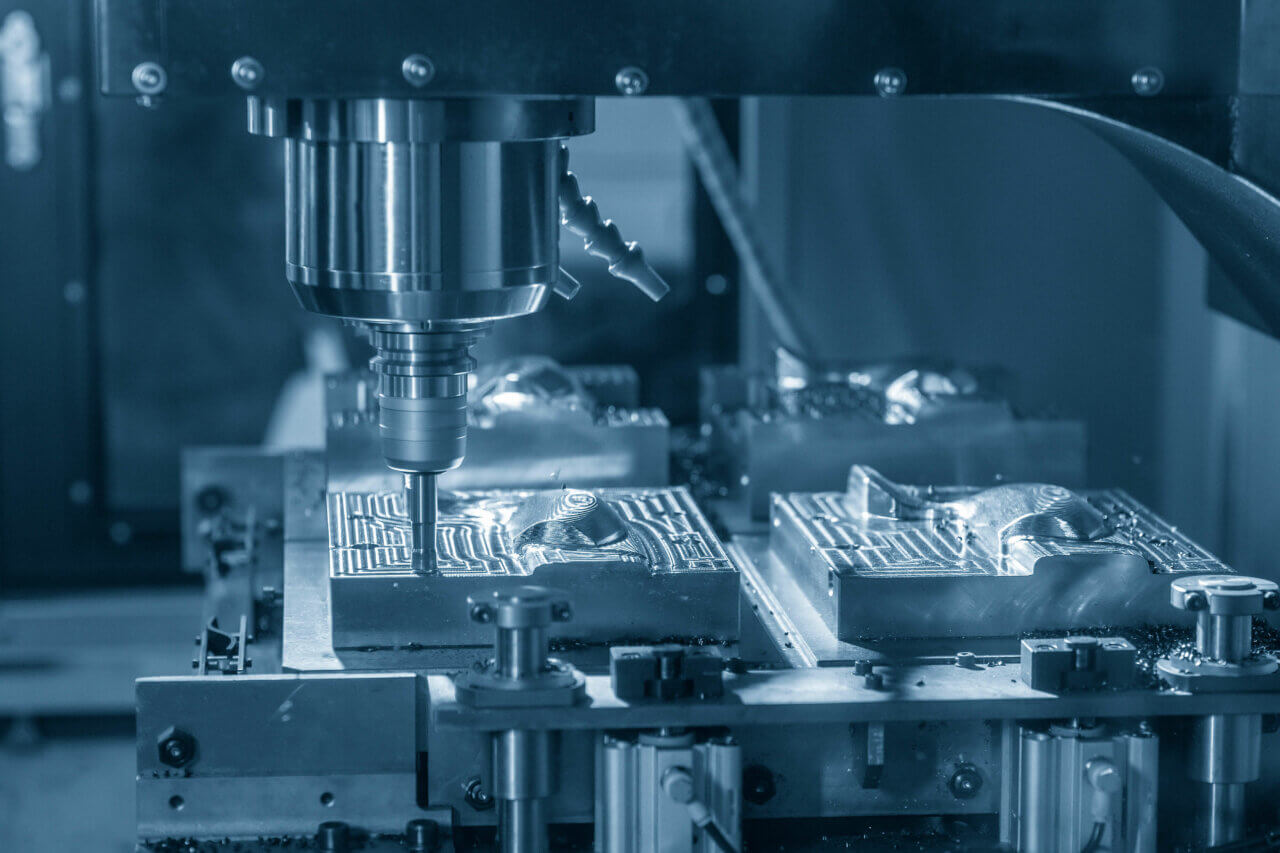

1. CNC Machining

CNC machining is one of the most common and versatile manufacturing methods for connector parts. Using computer-controlled cutting tools, CNC machines can shape metals like copper and brass with unmatched accuracy.

This process ensures each terminal or shell meets exact dimensional standards, resulting in consistent performance and easy assembly.

2. Wire EDM (Electrical Discharge Machining)

Wire EDM is used when components require ultra-fine details or complex shapes. By using electrical sparks to cut through metal, EDM produces smooth, precise edges without introducing mechanical stress.

This technique is ideal for miniaturized connectors used in compact electronic devices or precision instruments.

3. Micro Stamping and Die-Cutting

For high-volume production, micro stamping creates thousands of identical terminals and contacts quickly. Because the dies are engineered with high precision, the resulting parts maintain consistent shape and thickness—critical for secure electrical performance.

4. Injection Molding for Insulating Parts

Many connectors include plastic housings or insulation components. Through injection molding, molten plastic is injected into a precision mold to create consistent, dimensionally stable parts.

This process ensures perfect alignment between metal contacts and insulation, improving both safety and durability.

Material Precision and Surface Finishing

Material Selection

The choice of materials plays a huge role in connector performance. Precision machining allows the use of premium metals such as copper, brass, and beryllium copper, known for their conductivity and strength.

Surface Treatments and Coatings

To enhance reliability, connector surfaces are often coated with gold, nickel, or silver. These coatings improve conductivity and protect against oxidation or corrosion. Even coating thickness is controlled at the micron level to ensure stable, long-term performance.

Deburring and Polishing

After machining, each component undergoes deburring and polishing to remove microscopic imperfections. This prevents damage during assembly and guarantees smooth contact surfaces for better electrical flow.

Testing and Quality Control in Precision Manufacturing

Quality control is at the heart of connector reliability. Each part goes through rigorous testing before it reaches the customer.

- Dimensional Inspection– High-precision measuring tools confirm that parts meet design tolerances.

- Electrical Testing– Conductivity, resistance, and signal stability are verified.

- Mechanical & Environmental Testing – Connectors are tested under vibration, Hitze, and humidity to simulate real-world conditions.

- Automated Vision Systems – AI-based inspection cameras detect even the smallest flaws, ensuring consistent quality at every stage.

How Precision Machining Benefits Connector Reliability

Precision machining directly enhances connector performance in several key ways:

- Superior Fit and Contact Accuracy: Perfectly aligned components ensure strong electrical continuity.

- Durability and Strength: Machined parts resist wear, Vibration, and corrosion.

- Consistency Across Production: Automated processes guarantee uniform results in mass manufacturing.

- Reduced Maintenance and Failures: Fewer defects mean fewer repairs, saving time and costs for end users.

In short, precision machining turns ordinary connectors into high-reliability components that can withstand the toughest applications.

Applications Across Industries

Reliable, precision-machined connectors are used in a wide range of sectors, einschließlich:

- Automotive and EVs– for battery systems and sensors

- Telecommunications– for high-speed data and 5G networks

- Medical Equipment– for diagnostic and monitoring devices

- Aerospace and Defense– for mission-critical systems

- Industrial Automation– for robotics and control systems

Each of these industries demands connectors that perform flawlessly under pressure—and precision machining makes that possible.

Abschluss

Precision machining is more than just a manufacturing process—it’s the foundation of connector reliability. From CNC cutting and EDM shaping to detailed inspection and surface finishing, every step contributes to creating connectors that last longer, perform better, and meet the highest industry standards.

For businesses seeking custom, high-performance connectors, working with an experienced manufacturer like Qianwei Connector ensures superior results. With advanced machining capabilities and strict quality control, Qianwei delivers connector solutions that meet the demands of modern technology—every time.

FAQ

1. What is precision machining in connector manufacturing?

Precision machining is a process that uses advanced computer-controlled tools such as CNC and EDM machines to produce highly accurate connector components. It ensures that every part—like pins, contacts, and housings—meets exact design specifications for perfect fit, conductivity, and durability.

2. Why is precision machining important for connector reliability?

Precision machining ensures that each connector component is produced within very tight tolerances. This accuracy prevents poor fitting, unstable signals, or electrical resistance, all of which can cause failure. The result is a more reliable, longer-lasting connector that performs consistently under demanding conditions.

3. What materials are commonly used for precision-machined connectors?

High-quality metals such as copper, brass, and beryllium copper are commonly used due to their excellent electrical conductivity and strength. These materials are often coated with gold, nickel, or silver to improve corrosion resistance and ensure long-term reliability.

4. How does surface finishing affect connector performance?

Surface finishing techniques like Überzug, polishing, and deburring enhance both the mechanical and electrical properties of a connector. A smooth, clean surface ensures stable contact between terminals and reduces the risk of oxidation or signal loss over time.

5. What industries rely most on precision-machined connectors?

Precision-machined connectors are widely used in Automobil, Telekommunikation, Luft- und Raumfahrt, medizinisch, and industrial automation sectors. These industries demand connectors that maintain reliable performance under extreme temperatures, Vibration, and environmental stress.

6. Can I request custom-designed connectors for my application?

Absolut. Manufacturers like Qianwei Connector specialize in custom connector manufacturing, offering tailored solutions based on your electrical, mechanical, und Umweltanforderungen. From design and prototyping to mass production, each connector is engineered to fit your specific needs.

7. How are precision connectors tested for quality?

Each connector undergoes rigorous electrical, mechanical, and environmental testing. This includes continuity checks, resistance measurement, vibration tests, and corrosion exposure. Advanced inspection systems are also used to detect microscopic flaws and guarantee consistent quality.

8. What’s the difference between standard and precision connectors?

Standard connectors are suitable for general applications, while Präzisionssteckverbinder are manufactured with far tighter tolerances and stricter quality control. They offer superior reliability, signal stability, and longer lifespan—especially important in high-performance or mission-critical systems.

9. How can I find a reliable precision connector manufacturer?

Look for a company with advanced machining technology, strict quality inspection, Und custom design capability. A trusted manufacturer like Qianwei Connector provides full-service solutions—from design consultation and material selection to production and testing—ensuring you receive dependable, high-performance connectors for your application.