Anschlüsse are essential electrical devices that join two active components, allowing current or signals to flow seamlessly between them. They form the backbone of electrical systems, bridging isolated circuits and enabling devices to function as intended. Whether in industrial machinery, Unterhaltungselektronik, or automotive systems, connectors ensure the reliability of electrical pathways.

A loose or poorly connected terminal is one of the most common and critical causes of system failure. Improper connections can lead to localized heating, sparking, or even fire, which can disrupt operations and damage equipment. This is why locking connectors are vital—they secure connections, prevent accidental disconnection due to vibration or motion, and maintain electrical continuity in challenging environments.

This guide explores the most common types of locking connectors, their applications, and how to choose the right one for your needs.

Locking Connector Types

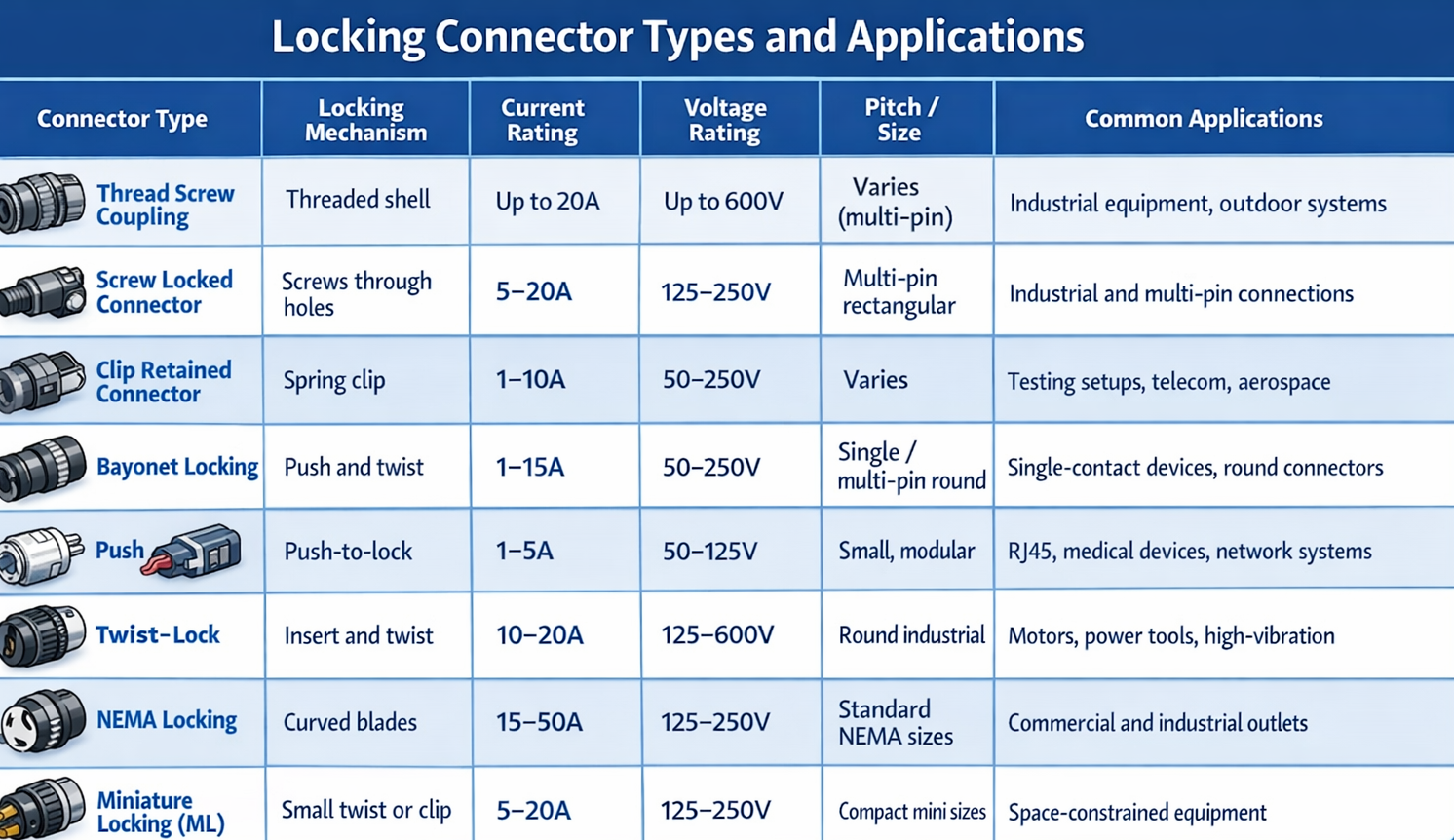

Locking mechanisms are designed to secure connectors in place, ensuring consistent electrical contact while protecting against environmental factors such as dust, moisture, and vibration. They also help align pins for connectors with multiple contacts. Common types of locking connectors include:

1. Thread Screw Coupling

Thread screw coupling connectors use a visual alignment of male and female pins followed by turning a threaded shell to lock the connection. The screw thread ensures firm mechanical engagement and provides protection against twists, dust, and water.

Advantages: Hohe mechanische Festigkeit, excellent environmental protection.

Limitations: Round design may occupy more panel space than rectangular alternatives.

2. Screw Locked Connectors

Screw-locked connectors use aligned holes and screws to secure rectangular or round connectors. They are common in multi-pin applications where vibration resistance is essential.

Anwendungen: Industrial equipment, machinery control systems.

3. Clip Retained Connectors

Also called clip-on connectors, these use a spring-loaded clip to secure the connector.

Advantages: Quick connect/disconnect for frequent maintenance.

Anwendungen: Testing setups, Telekommunikation, automotive electronics, Luft- und Raumfahrt.

4. Bayonet Locking

Bayonet-style connectors are simple but effective. They require aligning, pushing, and twisting to lock. A tactile click confirms secure engagement.

Anwendungen: Single-contact round connectors where a fast, reliable lock is needed.

5. Push and Release Connectors

Push-to-lock and press-to-release connectors are simple and user-friendly. Pushing engages the lock, while pressing a release tab allows removal.

Examples: RJ45 and RJ11 connectors used in telecommunication and network cabling, as well as some medical devices.

6. Twist-Lock Connectors

These connectors are inserted and then twisted to engage a secure lock. Twist-lock designs prevent accidental disconnection in industrial and high-vibration environments.

7. Other Locking Types

Breakaway Locking: Allows quick disconnect for non-technical applications, like fluid couplings.

Push-Pull Locking: Combines ease of use with secure engagement for various cable types.

Types of Power Connector Plugs

Mechanical plugs, used to link multiple electrical components, come in various designs depending on voltage and current requirements:

5-15P Plug: Standard North American 125V plug, common in household devices.

20-Amp Plug: Used in devices requiring higher power, including industrial equipment.

GFCI Plug: Ground Fault Circuit Interrupter plug for shock and fire protection in sensitive applications.

Electrical Connector Types

Electrical connectors vary based on application, Umfeld, and signal requirements. Some common types include:

Audio and Video Connectors: Microphones, telephones, commercial and military audio devices.

Automotive Electrical Connectors: Designed for vehicle electrical systems with high vibration resistance.

Board-to-Board Connectors: Embedded in PCBs for compact electronic designs.

Circular Connectors: Multipin connectors suitable for power, control, and signal transmission.

Coaxial Connectors: Central conductor insulated in a shield; used in high-data and CATV applications.

DIN Connectors: Round multi-pin connectors for high-frequency applications.

Centronics Connectors: Parallel interfaces for printers and peripherals.

D-Subminiature Connectors (D-Sub): Sturdy, polarized connectors with a D-shaped mating face.

Military Connectors (MIL-SPEC): Designed to withstand harsh environments and comply with military standards.

RJ and Modular Connectors: Data, telephone, and modular expansion systems.

NEMA Identification for Locking Connectors

In the US, NEMA standards regulate electrical connector design. Locking connectors are identified with an “L” in their naming, indicating a curved blade design that locks when inserted into a receptacle. Miniature locking connectors (“ML”) exist for applications with limited space.

Examples:

Two-pole, ungrounded, 125V

Two-pole, grounded, 125V

Three-pole, ungrounded, 125/250V

Correct identification ensures safe use and proper matching with the voltage and current requirements of the circuit.

How to Choose the Right Locking Connector

Selecting a suitable locking connector requires careful consideration of several factors:

Current Rating: Ensure the connector can safely carry the expected current.

Circuit Density & Connector Size: Minimize space without compromising electrical performance.

Lock Type: Passive locks allow simple disconnection; positive locks require deliberate disengagement.

Wire Size: Must match connector terminals for safe operation.

Leistung: Voltage, current, and signal transmission requirements must be met.

Environmental Conditions: Temperature, Vibration, and moisture tolerance are critical for reliable operation.

Abschluss

Locking connectors are essential for secure, reliable, and efficient electrical systems. By understanding the different types of connectors, their locking mechanisms, and performance characteristics, engineers and technicians can ensure uninterrupted operation even in harsh conditions. Proper selection, installation, and maintenance of connectors are crucial for long-term system stability and safety.

FAQs

- What is a locking connector, and why is it important?

A locking connector is an electrical connector that incorporates a mechanical mechanism to securely join two components. It prevents accidental disconnections caused by vibration, motion, or handling, ensuring reliable electrical continuity and system safety. - What are the main types of locking connectors?

Common types include thread screw coupling, screw-locked connectors, clip-retained connectors, bayonet locking, push and release connectors, twist-lock connectors, breakaway locking, and push-pull locking. Each type is designed for specific applications, environments, and current/voltage requirements. - How do twist-lock connectors work?

Twist-lock connectors are inserted into a receptacle and slightly rotated to lock in place. This mechanism prevents accidental disconnection, making them ideal for industrial, high-vibration, or heavy-duty applications. - What factors should I consider when choosing a locking connector?

Key considerations include current rating, voltage rating, circuit density, connector size, lock type (passive or positive), wire size, environmental conditions (temperature, moisture, Vibration), and performance requirements for signal or power transmission. - What is the difference between passive and positive locking systems?

Passive locking systems allow connectors to be disengaged with moderate force, while positive locking systems require deactivating a specific mechanism before separating the connectors. Positive locks are better for high-stress or high-vibration applications. - Are locking connectors used only for power applications?

NEIN. Locking connectors are used for power, data, and signal applications. Examples include audio/video equipment, Telekommunikation, Kfz-Verkabelung, medizinische Geräte, Industrielle Automatisierung, and military equipment. - What is a NEMA locking connector, and how is it identified?

NEMA locking connectors comply with U.S. standards for commercial and industrial outlets. They feature curved blades that lock into a receptacle when turned. The “L” in the connector name (e.g., NEMA L7-15P) indicates it is a locking type.