Push-on terminals (also called quick disconnect terminals or Faston terminals) are electrical connection components that are commonly used to obtain quick, reliable, and repeatable wire-to-eltic connections. They are indispensable in automotive, energy, automatisation industrielle, and consumer electronics industries due to their easy installation, good electrification, and the fact that they can be installed in conjunction with automated assembly.

Push-on terminals designed by Qianwei Precision are delivered at levels of operation to fulfill high current, high vibration, corrosion challenges, or both.

What Are Push-On Terminals?

Push-on terminals are flat-blade electrical connectors that present a secure connection through sliding on a matching male tab terminal. This relationship is based on the spring force and contact pressure, which ensures that the conductivity remains the same even though no screws or soldering are necessary.

They fall into the following categories:

- Male (tab) bornes

- Women (receptacle) bornes.

- Wholly and partially insulated.

- Locking and non-locking versions.

The design enables tool-free mating, fast maintenance, and replacement, which are major problems in high-volume production and field servicing.

Qianwei Engineering Design Principles

In terms of engineering, the performance of a push-on terminal is constrained by quite a few critical factors:

Contact Pressure and Retention Force

Controlled contact pressure is a significant element in the electrical reliability of push-on terminals. Well-controlled internal spring geometry in the female terminal produces enough normal force on the male tab to ensure low contact resistance and constant conductivity. Correct retention force also inhibits micro-arcing, fretting corrosion, and accidental disconnection under vibration and thermal cycling.

Electrical Conductivity

Optimization of contact surface geometry, high current using high-purity copper alloysise used to achieve high electrical performance as well as the control of plating thickness. A combination of these factors has minimized resistive losses, minimized localized heating, and preserved signal integrity, particularly in high current applications and signal-sensitive applications.

Mechanical Stability

Push-on terminals are constructed to resist multiple mating cycles, mechanical shock, and constant vibration. This renders them applicable in harsh conditions like automobiles and electric vehicle systems. Lock designs also improve mechanical security when they can resist accidental disengagement when operating under dynamic conditions.

Materials Used in Push-On Terminals

| Base Material | Electrical Conductivity (% IACS) | Key Mechanical Property | Typical Applications |

| Brass (Cu-Zn) | 25–30% | Good strength, easy forming | Automotive wiring, appliances, and general terminals |

| Phosphor Bronze | 15–20% | Excellent spring force, high fatigue resistance | Vibration-resistant connectors, control systems |

| Copper Alloys | 80–95% | High current-carrying capability | Power terminals, VE, and energy storage systems |

Overview of the Processes of Qianwei Manufacturing

Qianwei Precision uses highly automated operations with high precision control in producing the push-on terminals to assure high consistency in quality, performance,e and scalability to meet the needs OEM as well as in bulk production.

1. Raw Material Inspection

All the incoming materials are strictly checked concerning the chemical composition and mechanical properties to meet the requirements of the electrical performance andmechanical propertiess.

2. Rapid Accuracy Stamping

The stamping throughputs high-speed stamping enables tight dimensional control and consistent terminal geometry to produce a dependable fit and electrical contact performance.

3. Heat Treatment

Controlled heat treatment is used where necessary to maximize spring properties, enhancing retention force and mechanical stability over time.

4. Electroplating

Electroplating of terminals is done under a well-managed chemical bath to promote conductivity and resistance to corrosion, as well as surface durability.

5. Last Inspection and Testing

Extensive final checks and electrical inspection assure dimensional integrity, contact resistance, and a general product reliability before shipment.

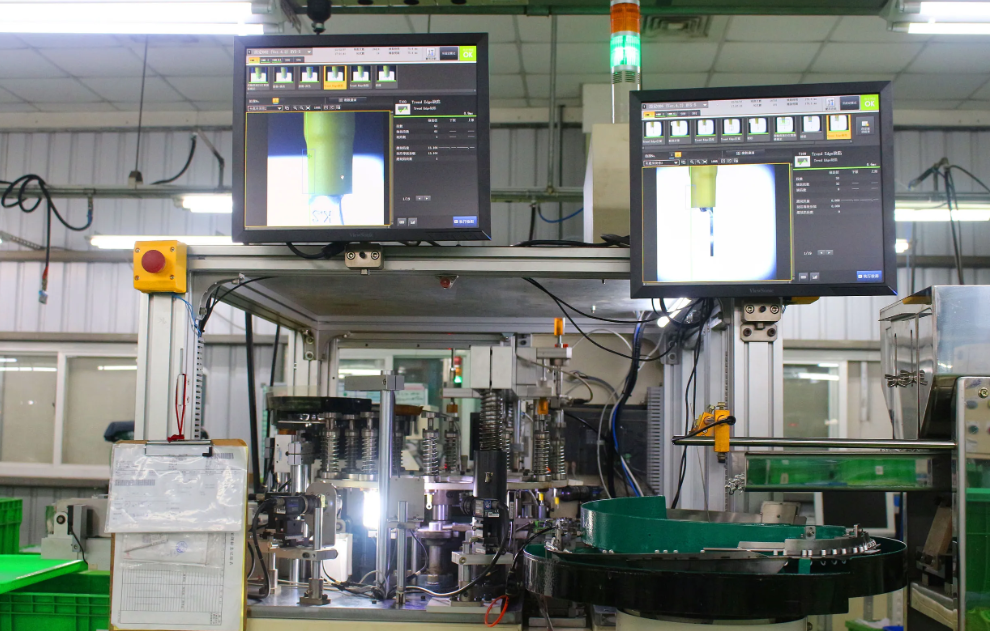

6. High-Level Automation

Qianwei Precision has a high degree of automation, over 98, which guarantees consistent quality, high productivity, and reliable supply when it comes to large-scale OEM.

Surface Finishes and Plating Technology

Surface plating is deposited on push-on terminals to minimize oxidation, increase the conductivity of the electrical circuit, and augment the corrosion resistance. Adequate surface treatment can achieve a stable electrical contact, extended service life, stable performance under conditions of variation in the environment and loading conditions.

Common Plating Materials

They may include;

- Tin plating- Tin plating is a low-cost, efficient option mainly applied in automobile and household appliance firms owing to its good conductivity and corrosion resistance.

- Nickel underlay is often used between the main plating to enhance wear through superior adhesion and limit diffusion or corrosion of the base metal.

- Silver plating is used in high current or low resistance critical systems where high conductivity and thermal stabilityares needed.

Chemical Engineering Compositions.

Chemically, plating thickness, grain structure, and surface morphology are important to consider regarding stability in thelong-term contact resistance. The controlled electroplating processes are standardized to assure consistent deposition, reduction of surface flaws, and consistency of electrical appearance during life in the services of that terminal.

Standard Sizes and Specifications of Push-On Terminals

Push-on Terminal Size Overview

n terminals are designed with a standardized width to facilitate compatibility and consistent mating with tab terminals windifferent industries all over the world.

| Terminal Width | Series Name | Typical Applications | Current Rating* |

| 2.8 mm | 110 Series | Signal circuits, sensors, low-power electronics | Up to 10 A |

| 4.8 mm | 187 Series | Medium-current control and appliance circuits | Up to 20 A |

| 6.3 mm | 250 Series | Automobile, industrial power distribution | Up to 30 A |

General Technical Specifications

Along with a terminal width, push-on terminals are characterized by such electrical, thermal, and insulation factors as distinguish their usability in particular applications.

| Parameter | Typical Range |

| Wire Size Range | 0.5–6.0 mm² (20–10 AWG) |

| Tension nominale | Up to 600 V |

| Operating Temperature | −40°C to +105°C (up to +125°C with special materials) |

| Insulation Types | PVC, Nylon (PA), Heat-resistant polymers |

| Plating Options | Tin, Nickel, Silver |

Push-On Terminal Applications in Industries.

Push-on terminals have been popular in various industries because they are simple to install, provide superior electrical operation, and withstand vibration and mechanical wear and tear.

Carmotive and New Energy Vehicles (NEV)

Push-on terminals are also employed in lighting circuits, sensors, actuators, battery management systems, and power distribution modules in automotive and NEV systems. They are suited to the current vehicle platforms due to their vibration resistance and rapid speed of servicing.

Power Systems/Storage of Energy

In the case of lithium battery packs, inverters,s and charging infrastructure, push-on terminals ensure consistent current delivery, whilst allowing compact design and quick assembly in large-scale production.

Home Appliances

Push-on terminals are employed in such household appliances as washing machines, air conditioners, and refrigerators to provide a cost-effective wiring solution, dependable long-term electrical contact, and easy maintenance.

Industrial Automation

Push-on terminals have been used in industrial automation to provide facilities in control panels, relais,s andmotor connectionsn where rapid installation, simple substitution, and stable operation are needed.

OEM Solutions and Customization.

Normal terminals might fail to accommodate all the application needs. Qianwei Precision provides tailored push-on terminal products, such as:

- Non-standard tab dimensions

- Corrosive special plating.

- Resistant to high temperatures.

- Specialized insulating material.

- Application locking.

Customized terminals can be created quickly using sophisticated mold design and in-house tooling, while adhering to high-performance requirements.

Quality and Compliance of Qianwei

All push-on terminals are produced in line with international standards of quality and safety, which are:

- RoHS and REACH compliance

- Traceability of automotive-grade material.

- Electrical and mechanical performance verification.

- Tight testing guarantees inter-product life cycle reliability.

Why Choose Qianwei Precision?

The selection of the connector supplier is very important in terms of performance, reliability, and manufacturability. Qianwei Precision provides quality terminals and tailored solutions supported by efficient production, excellent quality control, and robust OEM services.

1. High-tech Production Knowledge

Having more than 10 years of experience in precision terminals and connectors, as well as stamping, we now manufacture consistent, high-quality products out of high-speed automated production lines.

2. Extreme Accuracy and accuracy

We manufacture our terminals to exceedingly tight tolerances, with stringent quality and mechanical and electrical functionality, so that there is predictable contact, low resistance, and service life of the terminal.

3. Complete Portfolio and Personalized Solutions.

Our standard push-on connectors, our designed connectors, and our wire harnesses are one-stop solutions that address the unique needs of applications in industries.

4. Strong Quality Assurance

We will conduct a critical inspection of raw materials, exact stamping, controlled plating, and the last electrical test before every product can be marketed to satisfy industry standards.

5. Fast Lead Times and High Automation

Both standard and OEM orders enjoy scalable production opportunities and fast turn-in times with automation of over 98 percent.

6. OEM and Supply Support Worldwide

We can provide higher volume OEM supply at reasonable delivery services, full traceability, and advanced technical assistance in product selection and customization.

Conclusion

The use of push-on terminals has continued to be a fundamental part of today’s electrical interconnection systems because of their engineering simplicity, electrical reliability, and manufacturing efficiency. They provide high-performance stability in both industrial and commercial applications over a wide variety of operations when constructed with suitable material composition, surface treatment, and inspection of the dimensional aspect.

Qianwei Precision has more than 10 years of experience in precision stamping and connector production, to deliver high-quality push-on terminations and tailored-designed interconnect solutions to satisfy the workshop needs in the dealer-provided system in the referenced locations, which include automotive, energy, and industrial.

FAQs

What is a push-on terminal?

A push-on electrical connector (also known as the quick-disconnect connector) is a connector that fits on the appropriate male tab and offers a tool-free, dependable connection.

What are the typical push-on terminal sizes?

Common sizes are 2.8 mm (110 series), 4.8 mm (187 series), et 6.3 mm (250 series), with various current ratings and applications.

What are the materials used in push-on terminals?

They are generally composed of brass, phosphor bronze,e or copper alloys with surface plating often of tin, nickel, el or silver to enhance conductivity and resistance to corrosion.

Can push-on terminals be used in cars?

Oui, they are common in automotive systems because they avibration-resistantant, have secure contacts, and can be serviced quickly.

Are push-on terminals customizable?

Oui, Qianwei Precision can provide customers with special terminals that have special dimensions, plating, insulation, and lock design to satisfy individual use requirements.

What is the average operating temperature?

Most push-on connectors have a working temperature range of -40 °C to +1,05 °, C although high temperature versions can be used with heat-resistant materials.

No products were found matching your selection.