In today’s rapidly evolving automotive industry, electrical connectors play a crucial role in ensuring stable communication, safe power distribution, and reliable signal transmission across every vehicle system. As cars become more digitalized and electrified—integrating advanced sensors, ECUs, infotainment units, and EV high-voltage modules—understanding the different types of automotive electrical connectors becomes essential for manufacturers, technicians, engineers, and anyone working with vehicle electronics.

Modern vehicles can contain more than 1,500 connecteurs, each designed for specific environmental, electrical, and mechanical requirements. From waterproof connectors in harsh environments to high-voltage connectors powering electric vehicles, the right connector ensures safety, efficiency, and long-term reliability.

The Heart of Vehicle Electrical Systems

Automotive electrical connectors are the “gateways” through which all signals and electrical currents flow. They link sensors, control modules, actuators, lights, charging systems, batteries, and communication networks. Unlike older vehicles with simple wiring structures, modern vehicles use complex architectures that require robust, heat-resistant, waterproof, and vibration-resistant connectors to ensure consistent performance.

With today’s vehicles integrating ADAS, telematics, EV batteries, and infotainment systems, the demand for specialized connectors continues to grow.

Main Types of Automotive Electrical Connectors

Multi-Pin Automotive Connectors

These connectors allow multiple circuits to be connected simultaneously in a compact footprint.

Common applications:

-

Engine control units (ECUs)

-

Lighting systems

-

Body control modules

-

Infotainment systems

Multi-pin connectors support high-density wiring while ensuring stable signal integrity.

Sealed & Waterproof Automotive Connectors

Sealed automotive connectors are designed to block water, poussière, oil, and road contaminants.

Features include:

-

Silicone or rubber gaskets

-

Moisture-resistant sealing

-

Corrosion protection

They are used in:

-

Engine bays

-

Exterior lighting

-

Underbody sensors

-

EV battery systems

These waterproof connectors are essential for long-term durability in harsh environments.

Quick Disconnect Connectors

Quick disconnect connectors simplify vehicle maintenance and repair. They allow technicians to attach or detach wiring without cutting or soldering.

Ideal for:

-

Battery connections

-

Lighting systems

-

Safety modules

-

Diagnostic equipment

Their ease of use reduces downtime and improves service efficiency.

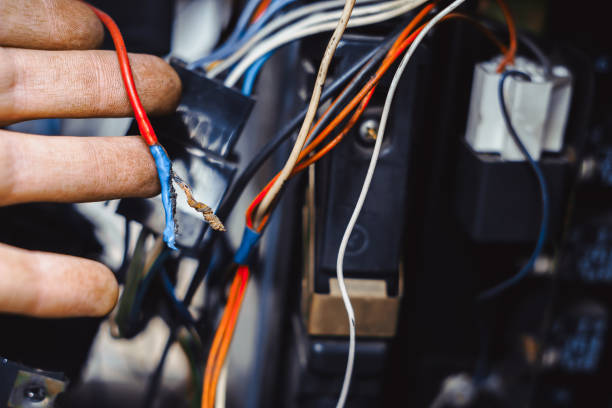

Automotive Wire Terminals: The Foundation of Reliability

Wire terminals enable a secure connection between the wire and the connector housing. Common types include:

-

Ring terminals

-

Spade terminals

-

Bullet terminals

-

Blade terminals

High-quality terminals are crucial for preventing voltage drops, intermittent signals, or wiring failures—especially in high-vibration areas like engines. Plating materials such as tin or gold help enhance conductivity and corrosion resistance.

Automotive pin removal tools are frequently used in workshops to extract or replace terminals without damaging the connector.

Waterproof and Sealed Connectors: A Critical Requirement

Waterproof connectors are essential in protecting automotive electronics from rain, humidity, car washes, and off-road environments.

Manufacturers conduct tests such as:

-

Salt spray testing

-

Vibration testing

-

Thermal shock testing

In electric vehicles, waterproofing becomes even more critical. A single moisture ingress incident can cause short circuits, sensor failures, or even battery damage. Modern sealed connectors are engineered to meet IP67 or IP68 standards for maximum protection.

High-Temperature & High-Voltage Connectors

High-Temperature Automotive Connectors

Used in extreme heat environments such as:

-

Turbocharged engines

-

Exhaust sensors

-

Under-hood power distribution

Made from specialized materials like PEEK or PTFE, these connectors maintain structural and electrical integrity even above 150°C.

High-Voltage EV Connectors

Electric vehicles require connectors capable of handling 400–800V or higher. These connectors must ensure:

-

High current carrying capacity

-

Multi-layer shielding (EMI protection)

-

Flame-retardant materials

-

Secure locking mechanisms

They are essential for EV batteries, inverters, motors, and high-power charging systems.

Automotive Plug and Socket Types

Automotive connectors consist of two main parts:

-

Plug (male)

-

Socket (female)

Different shapes—circular, rectangular, keyed—ensure proper alignment and prevent mismatching. Modern connectors include color coding and polarization to further reduce wiring errors during assembly.

Automotive Wiring Harness Connectors: The Vehicle’s Nervous System

Wiring harness connectors link all electrical components across the vehicle. As cars adopt more sensors and ECUs, the need for compact, lightweight, high-density connectors increases.

Key trends driving the wiring harness connector market:

-

Growth of EVs

-

Expansion of ADAS technology

-

Lightweight vehicle design

Market research predicts the automotive connector industry will surpass $25 billion by 2030.

Quick Disconnect Connectors in Maintenance

Quick disconnect connectors have become indispensable in automotive manufacturing and repair. They offer:

-

Fast replacement

-

Strong locking mechanisms

-

Corrosion-resistant contact points

This significantly reduces service time and improves safety during diagnostics and part swaps.

Comparison of Major Automotive Connector Types

| Type de connecteur | Primary Use | Environmental Resistance | Voltage Capacity | Service Ease |

|---|---|---|---|---|

| Sealed connectors | Engine bay, sensors | High | Medium | Medium |

| High-voltage EV connectors | EV batteries & power units | High | Very High | Complex |

| High-temperature connectors | Engine & exhaust systems | Very High | High | Moderate |

| Multi-pin connectors | ECUs, infotainment | Medium | Medium | Moderate |

| Quick disconnect connectors | Battery, lighting | Moderate | Medium | High |

Each connector type solves unique engineering challenges, ensuring vehicle systems operate safely and reliably.

Future Trends: Smarter, Smaller, and More Sustainable Connectors

The next-generation automotive connectors will feature:

-

Miniaturization for compact EV architectures

-

Smart diagnostics to monitor heat, corrosion, and voltage behavior

-

Eco-friendly materials and recyclable housings

-

Improved shielding to support advanced autonomous systems

As vehicles become smarter and fully electric, connectors will evolve to match the increasing demand for high-efficiency and high-reliability performance.

Conclusion

Automotive electrical connectors are essential components that support modern vehicle technology. From sealed waterproof connectors and high-voltage EV connectors to multi-pin and quick disconnect designs, each type plays a critical role in delivering power, communication, and safety. As the automotive industry continues to innovate, connectors will remain the unseen backbone that enables reliability, performance, and the future of mobility.