Introduction: Understanding Lock Connectors

Lock connectors play a critical role in modern electrical, mechanical, and structural systems. As devices and equipment become more compact, automated, and performance-driven, the demand for secure, vibration-resistant, and reliable connector solutions continues to grow.

From the perspective of a professional connector manufacturer, lock connectors are not simply fastening components—they are system-critical interfaces that directly affect product safety, performance stability, and service life. Selecting the right lock connector type and supplier is essential for OEMs, システムインテグレーター, and wiring harness manufacturers across industries such as automotive, 産業オートメーション, 家電, and construction.

This article provides a comprehensive, manufacturer-focused overview of lock connector design principles, 種類, functions, とアプリケーション, helping engineers and purchasing teams make informed decisions.

Design Principles and Key Factors of Lock Connectors

Strength and Durability

From a manufacturing standpoint, lock connectors must be engineered to withstand long-term mechanical stress, vibration, and repeated mating cycles. High-strength copper alloys, stainless steel, and reinforced engineering plastics (such as PA66 or PBT) are commonly used to ensure mechanical robustness and durability.

Material selection and structural design directly influence a connector’s load-bearing capacity and resistance to fatigue, especially in high-vibration environments like automotive engines or industrial machinery.

Ease of Installation

Efficient installation is a key requirement for modern production lines. Well-designed lock connectors allow quick assembly and disassembly, reducing labor time and minimizing installation errors.

Manufacturers often incorporate:

-

Snap-in or push-lock structures

-

Tool-free or low-force locking mechanisms

-

Clear tactile or audible locking feedback

These features are especially valuable in applications requiring frequent maintenance or modular replacement.

Connection Reliability

The primary purpose of a lock connector is to prevent accidental disconnection. Reliable locking mechanisms—such as secondary locks, latches, or positive locking tabs—ensure stable electrical or mechanical continuity throughout the product lifecycle.

From a quality control perspective, consistent contact pressure and precise tolerances are essential to maintaining signal integrity and current-carrying performance.

Environmental Resistance

Depending on the application, lock connectors may be exposed to moisture, ほこり, oil, 化学薬品, or extreme temperatures. Manufacturers enhance environmental resistance through:

-

Sealing structures and gaskets

-

Corrosion-resistant plating (錫, ニッケル, or gold)

-

UV- and heat-resistant housing materials

For harsh environments, IP-rated lock connectors are often required to ensure long-term reliability.

Main Types of Lock Connectors

Mechanical Lock Connectors

Mechanical lock connectors are primarily used for structural or load-bearing connections.

Common types include:

-

Bolts and nuts for high-strength fastening

-

Pins for alignment and positioning

-

Snap-fit connectors for quick assembly in lightweight applications

These connectors are widely used in machinery, automotive structures, and industrial equipment.

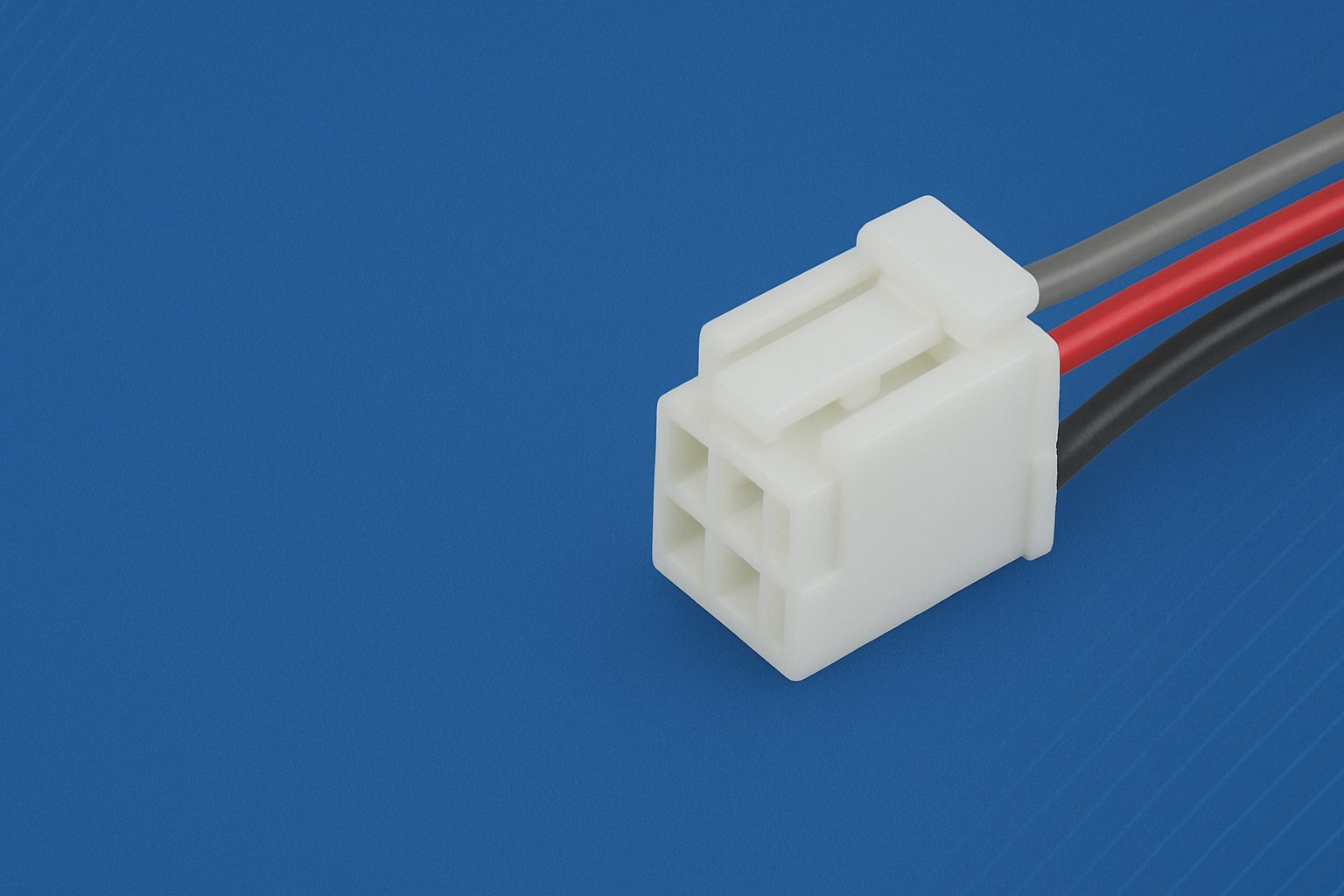

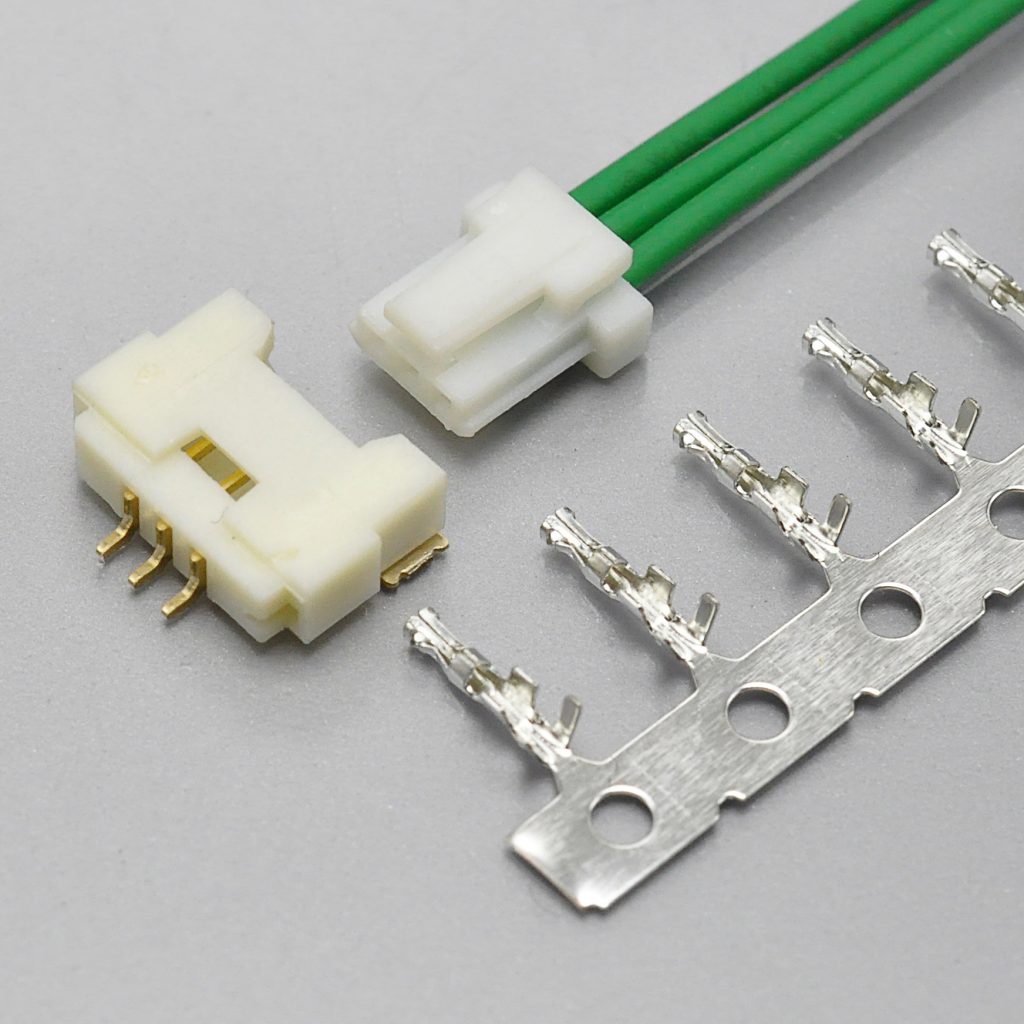

Electronic Lock Connectors

Electronic lock connectors focus on secure electrical connectivity.

Typical products include:

-

Plug and socket connectors for power and signal transmission

-

Locking electrical connectors that prevent vibration-induced disconnection

-

Wire-to-board connectors, essential in PCB assemblies and electronic modules

Manufacturers optimize these connectors for contact reliability, compact size, and high mating cycle performance.

Building and Structural Lock Connectors

In construction and infrastructure projects, lock connectors provide structural stability and safety.

Key products include:

-

Clamps and brackets for framework support

-

Anchor bolts for securing heavy equipment to concrete foundations

These connectors must comply with strict safety and load standards.

Functions of Different Lock Connector Types

Mechanical Lock Connector Functions

-

High mechanical strength and stability

-

Precise component alignment

-

Efficient assembly and disassembly

Electronic Lock Connector Functions

-

Reliable power and signal transmission

-

Protection against accidental unplugging

-

Compact solutions for high-density assemblies

Structural Lock Connector Functions

-

Maintaining structural integrity

-

Even load distribution

-

Flexibility for system expansion or modification

Applications of Lock Connectors Across Industries

Automotive Industry

-

Engine and transmission assemblies

-

Wiring harnesses and ECUs

-

センサー, lighting systems, and control modules

Consumer Electronics

-

Smartphones, tablets, and wearable devices

-

Home appliances requiring compact, secure connections

産業機械

-

Automated production lines

-

Robotics and motion control systems

-

Heavy-duty construction and mining equipment

Building and Construction

-

Structural frameworks and support systems

-

Electrical wiring installations

How to Choose the Right Lock Connector Manufacturer

From a B2B purchasing perspective, selecting the right manufacturer is just as important as choosing the connector type.

Reputation and Industry Experience

An experienced manufacturer understands application-specific requirements and industry standards.

Product Range and Customization Capability

A broad product portfolio and custom design support ensure compatibility with unique system requirements.

Quality Standards and Certifications

Compliance with ISO, UL, RoHS, and other certifications guarantees consistent product quality.

Technical Support and After-Sales Service

Strong engineering support helps customers optimize connector selection and integration.

Innovation and R&D Capability

Continuous investment in R&D leads to improved performance, miniaturization, and cost efficiency.

結論

Lock connectors are essential components that ensure 機械的安定性, electrical reliability, and operational safety across a wide range of industries. From automotive wiring harnesses to industrial automation and construction systems, the correct lock connector solution directly impacts product performance and longevity.

By understanding lock connector types, design principles, and application requirements—and by partnering with a professional connector manufacturer—OEMs and system integrators can achieve higher reliability, efficiency, and long-term success. お問い合わせ 詳細については.

よくある質問

1. What is the difference between a primary lock and a secondary lock (TPA/CPA)? A primary lock is the main mechanism (like a latch or snap) that holds the connector together. A secondary lock, often called a Terminal Position Assurance (TPA) or Connector Position Assurance (CPA), is an additional safety feature. It ensures that the terminals are fully seated and prevents the primary latch from accidentally opening due to extreme vibration or pulling.

2. How do I determine which IP rating my lock connector needs? の IP (Ingress Protection) rating depends on the operating environment. If the connector is used inside a sealed electronic box, a basic rating may suffice. しかし, for automotive under-the-hood or outdoor industrial applications, IP67 (immersion) or IP69K (high-pressure washdown) is usually required to protect against moisture and dust.

3. Why is “audible feedback” mentioned as a design principle? In high-volume assembly lines, workers may not always have a clear line of sight to the connector. A distinct “click” sound (audible feedback) and a tactile “snap” (tactile feedback) confirm that the lock is fully engaged, significantly reducing the risk of “half-mating,” which leads to intermittent signal failures.

4. Which contact plating is best for high-vibration environments? While 錫 is cost-effective, gold plating is often preferred for low-voltage signal connectors in high-vibration environments. Gold is highly resistant to oxidation and “fretting corrosion”—the microscopic wear caused by constant vibration that can lead to increased electrical resistance.

5. Can lock connectors be reused, or are they one-time use? Most industrial and electronic lock connectors are designed for multiple 嵌合サイクル. しかし, the durability depends on the material. Plastic snap-fits may weaken or stress-whiten after repeated use, while metal screw-locks or heavy-duty bayonet styles are designed for hundreds of cycles. Always check the manufacturer’s “mating cycle” specification.

6. How do lock connectors handle thermal expansion? High-quality manufacturers use engineering plastics like PBT or PA66 and specific geometric designs that allow for slight material expansion and contraction without compromising the integrity of the lock or the electrical contact pressure.

7. Are there “tool-free” lock connectors for heavy-duty industrial use? はい. Push-pull そして bayonet-style locking mechanisms are common tool-free solutions. They provide the security of a threaded screw-lock but can be engaged and disengaged quickly by hand, which is ideal for field maintenance and tight spaces.

8. What are the signs of a failing lock connector? Common warning signs include intermittent signals, physical discoloration (due to overheating from high resistance), loose housing movement, or a “soft” engagement feel where the connector no longer clicks securely into place.