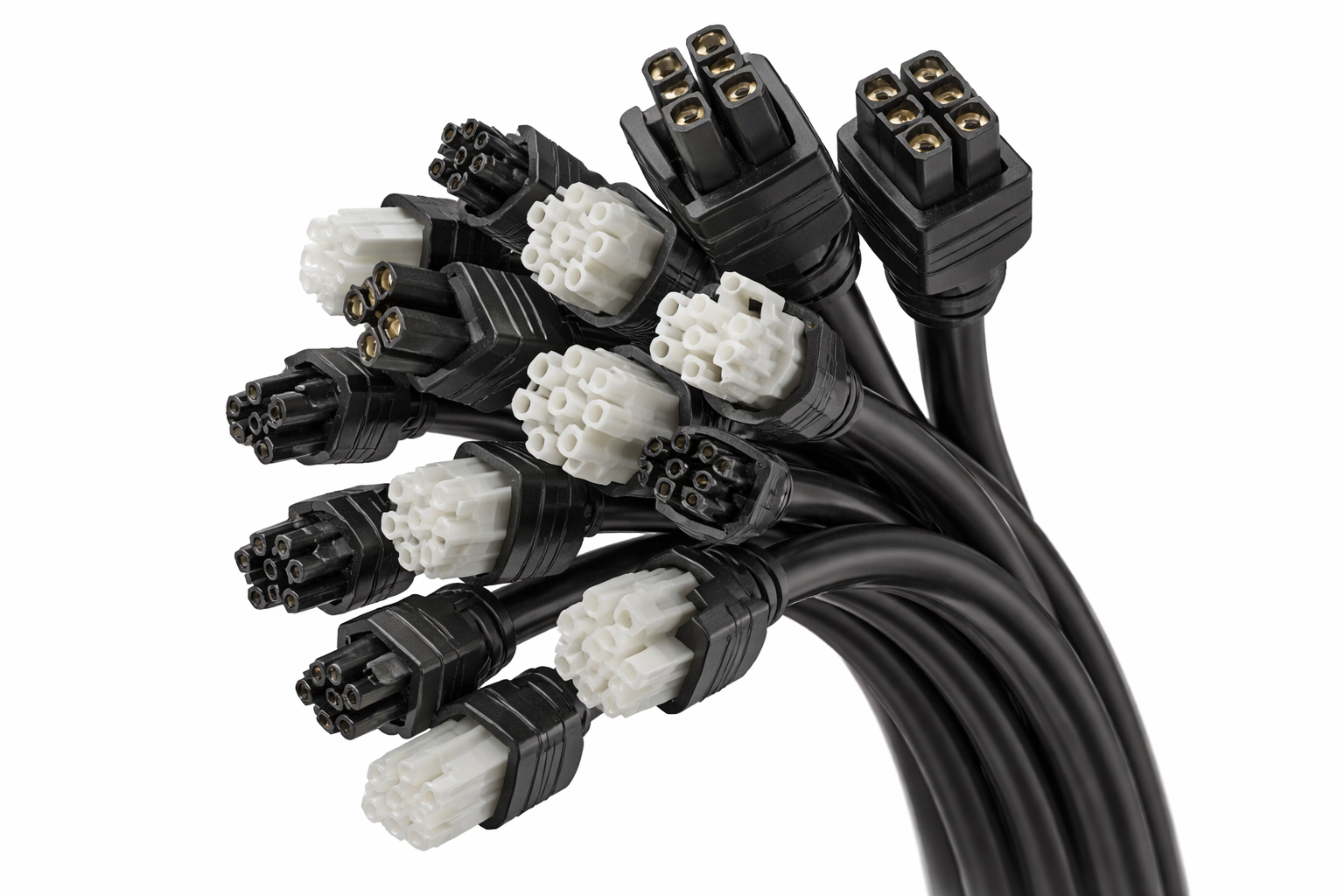

Overmolding has revolutionized cable assembly manufacturing over the past few decades. Through the advanced injection molding process, overmolded cables have evolved to offer superior functionality, protection, and aesthetics, allowing them to meet the demands of harsher environments and more complex applications. The process involves encasing a cable assembly in a protective layer, typically made of thermoplastic or thermoset materials, that offers enhanced protection from physical damage, 水分, 化学薬品, and more. Today, overmolding is widely used across industries ranging from aerospace to automotive to medical, thanks to its ability to improve performance and extend the lifespan of cable assemblies.

The Benefits of Overmolded Cable Assemblies

Environmental Resistance

One of the major advantages of overmolding is its ability to make cable assemblies resistant to a variety of environmental factors. Overmolded assemblies can become impervious to fluids, such as water, oil, or other chemicals, which is crucial in industries like marine, 自動車, or medical devices. These cables can be used in environments where exposure to moisture or contaminants is common, ensuring that the internal components remain protected and continue functioning optimally.

Enhanced Durability

Overmolding also provides superior mechanical protection. The molded layer makes the cable more resistant to shock, vibration, and constant flexing. This is especially important for cables that are used in equipment subject to movement, such as robotics, heavy machinery, or military applications. The added protection helps prevent damage at the termination points, which are often the most vulnerable parts of a cable assembly.

Aesthetic Customization

Overmolding offers significant opportunities for aesthetic customization. Companies can add logos, trade names, or unique designs to the molded layer, which is both a branding tool and a means of enhancing the visual appeal of a product. The overmolded material can be molded into various colors, textures, and patterns, giving manufacturers a chance to differentiate their products while maintaining high performance.

Rapid Prototyping and Testing

Thanks to advancements in 3D printing, creating prototypes of overmolded cables has become faster and more cost-effective. Before committing to expensive hard tooling, manufacturers can produce quick models of the overmold using 3D printing. This allows them to test the design, fit, and function of the overmold, making adjustments as needed before mass production.

Overmolding Design Considerations

When designing an overmolded cable assembly, engineers must carefully consider several factors to ensure the final product meets performance standards.

Strain and Bend Relief

Overmolding can provide crucial strain and bend relief, which are especially important at the points where cables connect to connectors or housings. Grommets, backshells, and molded bends protect the cables from excessive stress or wear, ensuring that the cable maintains its functionality over time.

Material Selection

The choice of material used for the overmolding plays a significant role in the performance of the cable assembly. Engineers must consider factors such as flexibility, resistance to environmental stressors, and compatibility with the cable being overmolded. The material must also align with the expected operating conditions of the end-use application, whether that’s extreme temperatures, exposure to chemicals, or mechanical stress.

Tooling Complexity

The complexity of the tooling required for overmolding has increased with the advent of new materials and advanced designs. Molds must be carefully engineered to accommodate the specific geometry of the cable assembly and overmold, which can include additional features like grommets or connectors. As designs become more complex, manufacturers need to balance the need for precision with the cost and time required for mold fabrication.

Prototyping with 3D Printing

One of the most important steps in overmolding design is prototyping. Using 3D printing for creating early-stage overmold designs has become a game changer. Engineers can quickly produce low-cost prototypes to test form and fit before moving forward with expensive tooling. This is particularly beneficial for projects with unique or complex designs, where iterative testing is necessary to achieve the right results.

Cable Assembly Overmolding Process

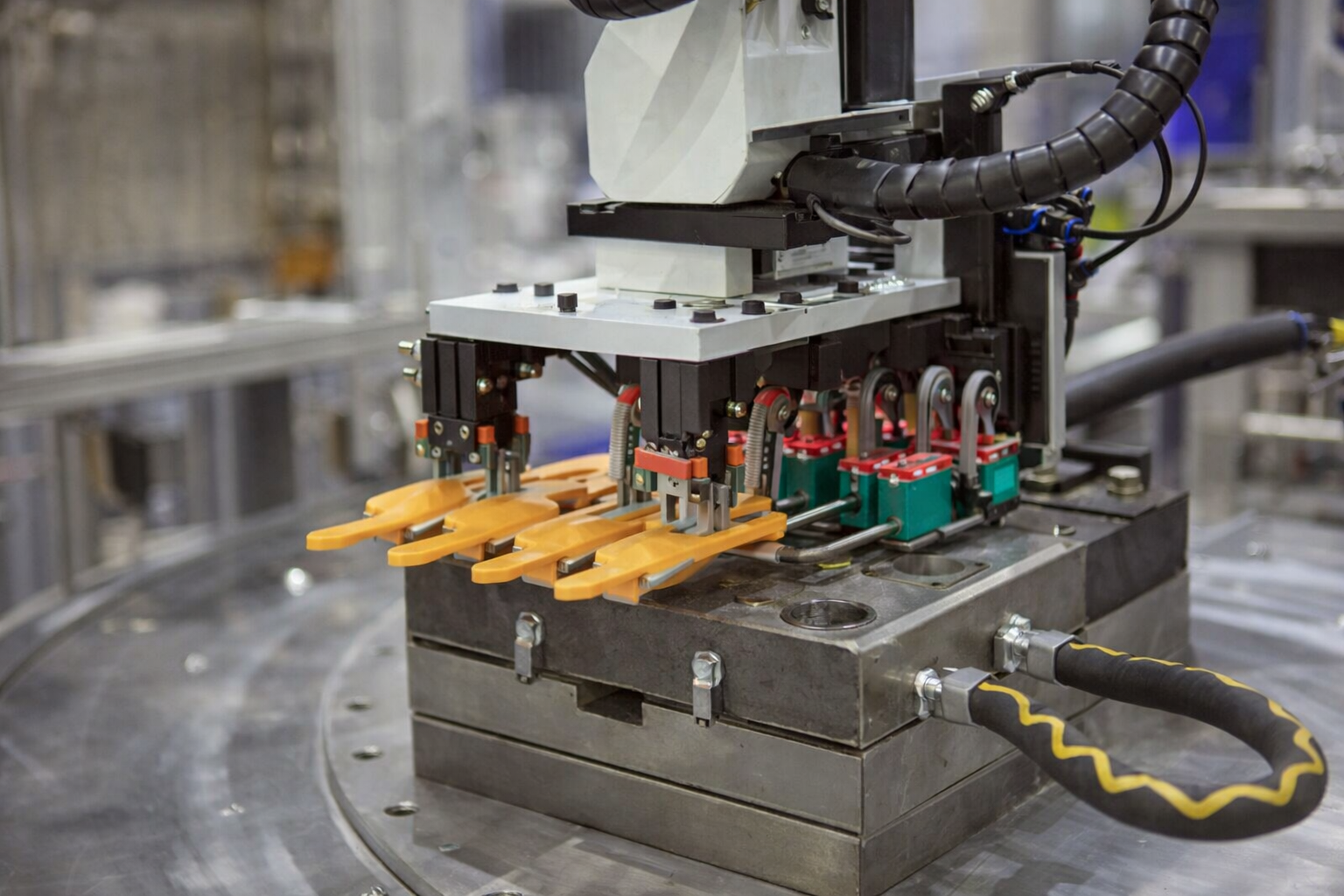

Overmolding a cable assembly is accomplished through a process known as injection molding. The process involves injecting a molten resin material into a mold cavity under high pressure.

Injection Molding Setup

The injection molding machine, often referred to as a press, is the key piece of equipment used in overmolding. It consists of several components, including the hopper (which holds the resin), a screw-type plunger or injection ram that moves the resin through the barrel, and heating elements that melt the resin to a liquid state. Once the resin reaches the desired viscosity, it’s injected into the mold cavity, where it cools and solidifies to form the overmolded layer.

Material Options

The most common materials used for overmolding are thermoplastics and thermosets, both of which offer unique advantages. Thermoplastics, like PVC and TPE, can be reprocessed and molded multiple times, while thermosets like polyurethane or silicone provide excellent thermal stability and resistance to chemical exposure. The choice of material depends on the specific requirements of the application, including flexibility, 耐久性, 耐環境性.

Injection Molding Tools and Materials

Overmolding requires the use of molds, which are precision tools designed to shape the resin material into the desired final product. The materials used for mold fabrication and the design of the mold itself are crucial factors in the quality and consistency of the overmolded assembly.

Tooling Materials

Molds for overmolding can be made from various metals, including hardened steel, aluminum, or even 3D-printed materials for low-volume or prototype runs. Hardened steel molds are ideal for high-volume production because they offer excellent durability and can withstand thousands of molding cycles. Aluminum molds, while less durable, are often used for prototyping or lower-volume runs due to their cost-effectiveness and faster production times.

Machine Tonnage

The tonnage of the injection molding machine refers to the amount of force the machine can exert to keep the mold closed during the injection process. Larger molds require higher tonnage to ensure that the resin flows correctly and fills the cavity. This factor must be considered when selecting an injection molding machine for a specific application.

Single vs. Multiple Cavity Designs

Molds can be designed with one or more cavities, depending on the desired output.

Single-Cavity Molds

A single-cavity mold is designed to produce one part at a time. While this method is simple, it can be less efficient for high-volume production runs.

Multi-Cavity Molds

Multi-cavity molds can produce several identical parts during a single molding cycle. These molds are more complex and require careful engineering to ensure the resin flows evenly into each cavity. In some cases, multi-cavity molds are designed to produce parts with different shapes or sizes, though this can present challenges in maintaining consistent resin flow.

Pre-Mold and Overmold Designs

In some applications, pre-molded parts like screws or connectors are inserted into the mold before the overmolding process begins. This allows the resin to flow around these components, creating a secure and functional assembly.

Appearance of the Finished Product

The molding process can result in some visible imperfections on the surface of the final product, such as marks where the resin entered the mold, or blemishes caused by the mold tooling. While these imperfections are often unavoidable, they can be minimized by specifying tight dimensional tolerances in the mold design. The placement of gates, which are the points through which resin enters the mold, can also be strategically planned to reduce the visibility of marks.

Summary

Overmolded cable assemblies have come a long way in terms of both performance and design flexibility. The evolution of materials and manufacturing processes, such as 3D printing for prototyping, has made overmolding an accessible and valuable technique for creating durable, high-performance cable assemblies. As the demand for rugged, reliable, and aesthetically pleasing cable solutions continues to grow, overmolding will remain an essential part of the cable assembly industry, providing manufacturers with the tools they need to meet the challenges of today’s dynamic market. お問い合わせ 詳細については.

よくある質問

- What is an overmolded cable assembly?

An overmolded cable assembly is a cable that has been encased in a protective layer, typically made of thermoplastic or thermoset material, through an injection molding process. This layer provides enhanced protection from physical damage, 水分, 化学薬品, and other environmental factors. - What are the key benefits of overmolding for cable assemblies?

Overmolding enhances the durability, environmental resistance, and aesthetics of cables. It provides strain relief, protects against moisture and chemicals, and allows for customization, such as adding logos or brand names to the cable. - How is the overmolding process done?

The overmolding process involves injecting molten resin into a mold cavity under high pressure. The material cools and solidifies to form a protective overmold around the cable assembly, offering superior protection and functionality. - What materials are used for overmolding?

Common materials for overmolding include thermoplastics like PVC and TPE, and thermosets such as polyurethane and silicone. The choice of material depends on the application’s specific requirements, including environmental resistance, 柔軟性, and durability. - Can 3D printing be used for overmolding prototypes?

はい, 3D printing is often used to create low-cost prototypes of overmolded designs. This allows engineers to test the form and fit of the overmold before committing to expensive tooling. - What is the difference between single and multi-cavity molds?

A single-cavity mold produces one part at a time, while a multi-cavity mold can produce multiple identical parts in one cycle. Multi-cavity molds are more efficient for high-volume production. - How do overmolded cables improve durability?

Overmolding protects cables from physical damage by providing strain relief, shock resistance, and shielding against harsh environmental conditions, such as moisture, 油, or chemicals. - What industries benefit from overmolded cable assemblies?

Overmolded cable assemblies are used in a variety of industries, including automotive, 航空宇宙, 医療機器, military, および産業用途, where durability, environmental protection, and customization are essential.