In electrical wiring systems, maintaining strong and secure connections is essential to ensure the safe and efficient operation of circuits. Among the many types of electrical terminals available, butt splice connectors are one of the most frequently used components for joining two wire ends together. Designed with insulation materials such as vinyl or nylon and equipped with metal crimp barrels, these connectors offer a dependable solution for wire repair, extension, and new installations. This comprehensive guide explores the features, 種類, アプリケーション, and selection tips for butt splice connectors, helping you choose the right products for your electrical projects.

What Are Butt Splice Connectors?

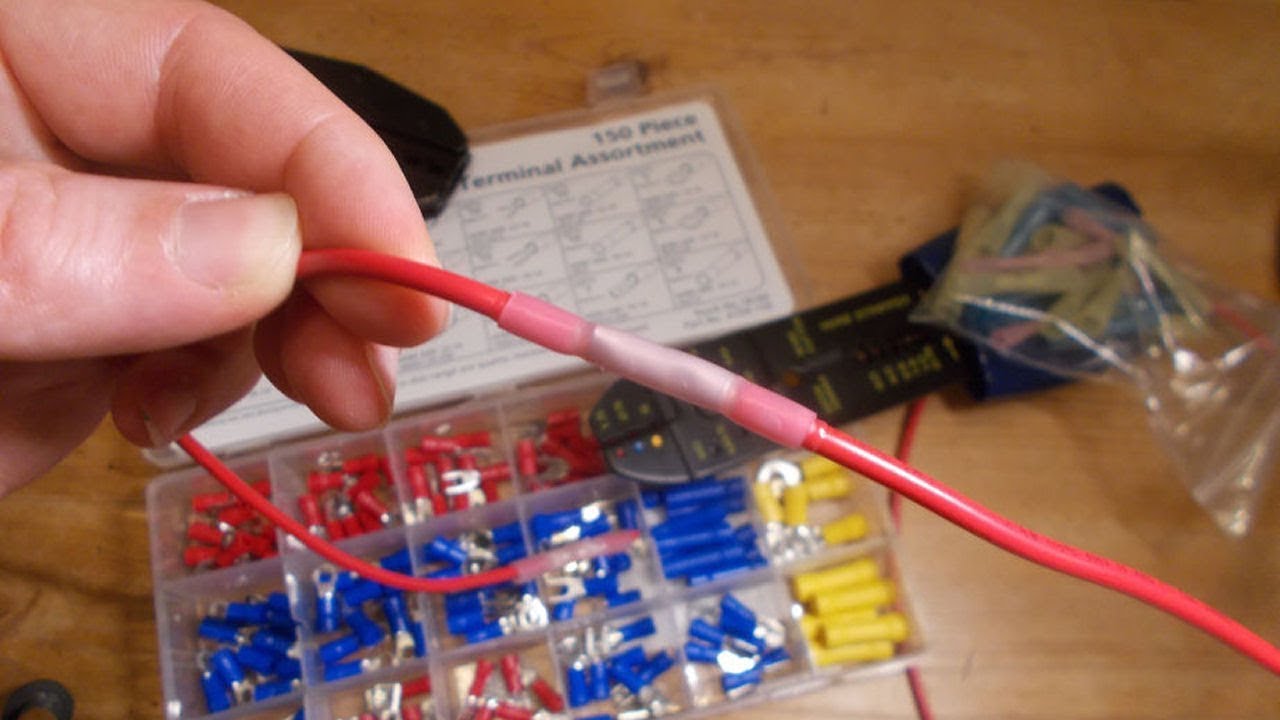

A butt splice connector is a type of crimp-style connector used to link two opposite wire ends, creating a continuous electrical path. The wires are inserted from both ends of the connector and secured using a crimping tool. Butt splices are widely used in automotive wiring, 家電, industrial equipment, marine systems, and network installations.

Because of their ease of use and reliable performance, butt splice connectors are considered essential components for electricians, technicians, and engineers.

Key Features to Consider When Selecting Butt Splice Connectors

Choosing the right butt splice connector ensures long-term durability and electrical integrity. Before making a selection, consider the following important features:

Insulation Material

-

Nylon: Offers excellent toughness, 柔軟性, and resistance to abrasion. Ideal for heavy-duty or industrial applications.

-

Vinyl (PVC): A cost-effective alternative suitable for general-purpose wiring tasks.

-

Heat Shrink: Provides a watertight seal and enhanced environmental protection.

Voltage Rating

Most standard butt splice connectors handle up to 600V, which is suitable for automotive, commercial, and industrial use. Always check voltage specifications to match the connector with your application.

UL Listing & Certification

To ensure quality and safety, choose connectors that meet UL standards, such as UL486A or UL486C. Certified connectors ensure proper conductivity, flame resistance, and mechanical strength.

Metal Conductor Material

-

銅: The most common choice for high conductivity.

-

Nickel-Plated Steel: Used in harsh or high-temperature environments where corrosion resistance is critical.

Useful Facts About Butt Splice Connectors

Connects Opposite Wire Ends with Ease

Butt connectors create a secure joint by connecting two wires end to end. This is especially useful for:

-

Extending wire length

-

Repairing damaged wiring

-

Joining multi-wire cables

Color Coding by Wire Gauge

To simplify installation, butt splice connectors follow a universal color standard:

-

Red: 18–22 AWG

-

Blue: 14–16 AWG

-

Yellow: 10–12 AWG

This eliminates guesswork and reduces wiring errors.

Heat-Shrink Butt Splice Connectors

Heat-shrink connectors include an inner adhesive lining that melts when heated, sealing the connection against:

-

Moisture

-

Dust

-

Corrosive elements

These connectors are ideal for automotive, marine, and outdoor environments where durability is essential.

Insulated vs. Non-Insulated Butt Splices

-

Insulated connectors: Provide shock protection and are recommended for most applications.

-

Non-insulated connectors: Used where space is limited or where insulation is added later. They are economical and allow easy visual inspection of the crimp.

High-Temperature and Specialty Butt Connectors

Certain specialty butt connectors are engineered for extreme environments, capable of withstanding temperatures up to 900°F (482°C). These are commonly used in high-heat industrial systems or near engine compartments.

Solder Splice Connectors

Solder butt connectors combine the benefits of crimping and soldering. They contain:

-

A solder ring

-

Heat-shrink tubing

-

Waterproof adhesive

When heated, the solder melts, forming a strong mechanical and electrical bond.

Importance of Proper Crimping

A strong crimp ensures:

-

Stable electrical conductivity

-

Prevention of oxidation and corrosion

-

Long-term reliability and safety

Using a high-quality crimping tool and selecting the correct connector size are key to achieving a flawless connection.

Why Choosing a Reliable Butt Splice Connector Supplier Matters

To guarantee performance, longevity, and compliance with industry standards, always source connectors from trusted manufacturers or suppliers. High-quality butt splice connectors should be:

-

UL-listed

-

Manufactured with premium insulation and metal materials

-

Designed for consistent crimping performance

-

Compatible with various wire gauges and applications

Reliable suppliers provide products that support wire termination, routing, insulation, and overall electrical safety.

結論

Butt splice connectors are essential components for creating safe and reliable wire connections in automotive, 工業用, commercial, and residential electrical systems. By understanding the different types, features, and uses of these connectors, you can confidently choose the right solution for your wiring projects.

Whether you’re repairing wiring, extending cables, or installing new electrical systems, selecting high-quality butt splice connectors—and sourcing them from reputable manufacturers—ensures durability, 安全性, and long-term performance.

よくある質問

How do you properly crimp a butt splice connector?

To crimp a butt splice connector, insert each stripped wire into the connector barrel until it stops, then use a ratcheting crimping tool to firmly compress the metal sleeve. A proper crimp should feel solid and should not allow the wire to pull out.

When should I use heat-shrink butt splice connectors?

Heat-shrink butt splice connectors are recommended for outdoor, marine, 自動車, and high-moisture environments. The heat-shrink tubing seals the connection with adhesive, providing superior waterproofing and corrosion protection.

Are butt splice connectors safe for automotive wiring?

はい, butt splice connectors are widely used in automotive wire repair and modifications. Insulated or heat-shrink types are preferred because they offer vibration resistance, strong conductivity, and long-term durability.

What is the difference between insulated and non-insulated butt splice connectors?

Insulated butt connectors include a protective outer sleeve (nylon, vinyl, or heat shrink) for electrical safety. Non-insulated versions are cheaper and allow visual inspection of the crimp but require additional insulation after installation.

How do I choose the right size butt splice connector?

Connector size is determined by wire gauge. Follow universal color codes: 赤 (18–22 AWG), 青 (14–16 AWG), and yellow (10–12 AWG). Choosing the correct size ensures proper crimp strength and optimal electrical performance.