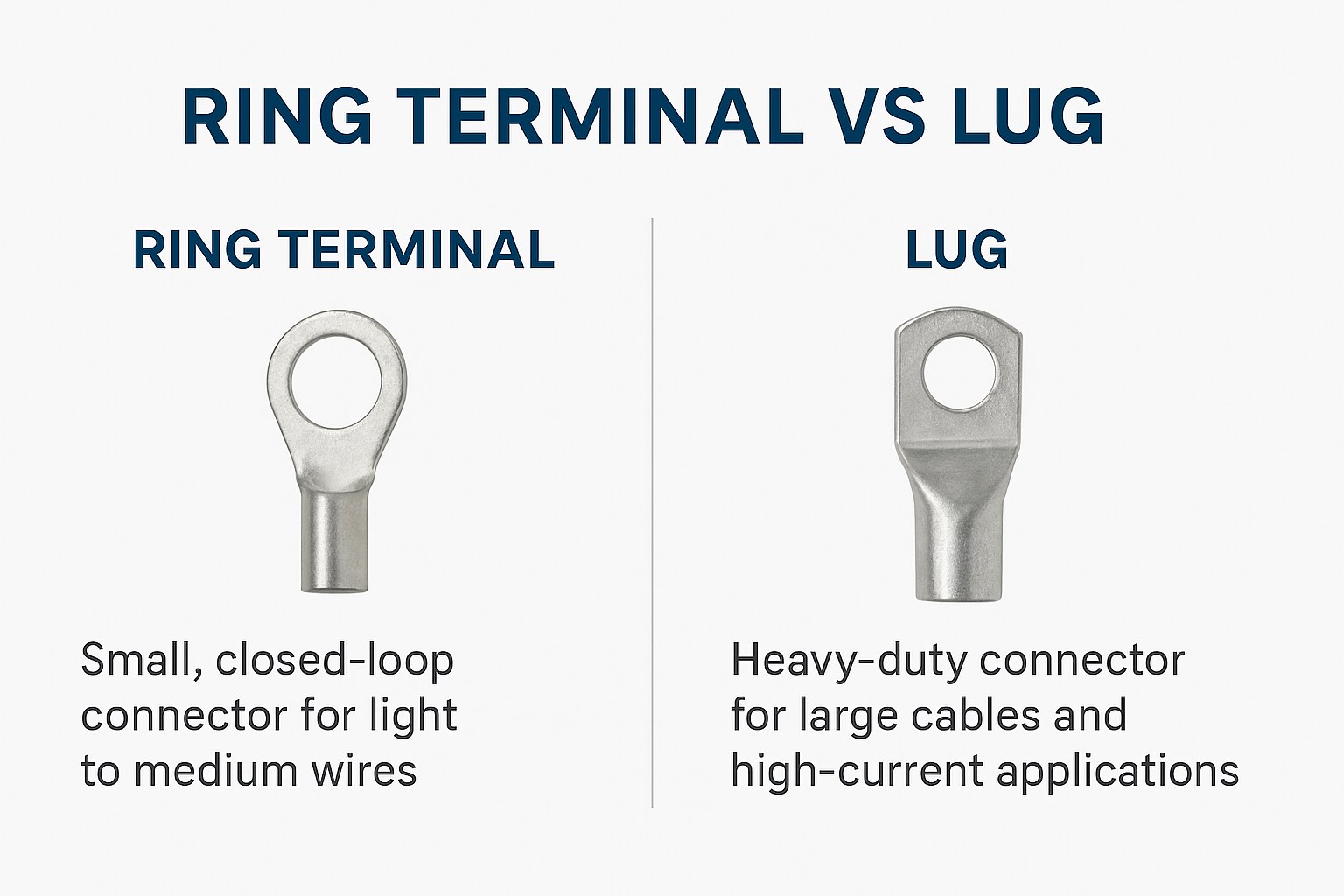

When working with any electrical system—whether on a vehicle, machine, or industrial power network—choosing the correct connector is essential for safety and long-term performance. Among the many available connection types, ring terminals そして lugs are two of the most commonly used. Although they may appear similar, they are designed for different applications and have very different load-handling capabilities. This guide explains the difference between ring terminals and lugs, how they work, and how to choose the right one for your project.

What Is a Ring Terminal?

あ ring terminal is a type of electrical terminal with a closed circular end that fits securely over a screw or bolt. The closed-loop design ensures that the wire cannot come loose even under vibration, 動き, or thermal expansion.

Key Characteristics of Ring Terminals

-

Closed-loop design: 不用意な断線を防止.

-

Stable electrical contact: Larger surface contact area ensures reliable conductivity.

-

Ideal for smaller wires: Typically used with small to medium gauge wires.

-

Quick installation: Usually attached using a standard crimping tool.

Common Applications

-

Automotive wiring

-

Small machines and equipment

-

Control panels

-

Grounding connections

-

Light power circuits

Their simplicity, 信頼性, and vibration-resistant design make ring terminals a preferred choice for stable, low- to medium-current circuits.

What Is a Lug?

あ lug is a heavy-duty connector designed for medium to very large cables. Unlike ring terminals, lugs are not limited to a single shape— they may have a ring end, spade end, flat pad, or compression pad depending on the application.

Key Characteristics of Lugs

-

Built for high-current loads: Thick material and large contact area support heavy power transmission.

-

Supports multiple installation methods: Crimping, hydraulic crimping, soldering, or bolting via compression.

-

Designed for large wire gauges: Suitable for power cables, battery cables, and industrial conductors.

-

Durable construction: Often made from copper or tinned copper for excellent conductivity.

Common Applications

-

Industrial power distribution

-

Motor and machinery wiring

-

Battery cable connections

-

Main AC and DC power lines

-

Renewable energy systems (solar, inverter, storage batteries)

Lugs are essential in environments where cables must carry large amounts of current safely and consistently.

Key Differences Between Ring Terminals and Lugs

Although both are used to create secure wire-to-bolt connections, their differences are clear:

Structure & Strength

-

Ring terminals: Lightweight, thinner construction.

-

Lugs: Thick, heavy-duty design built to handle heat and load.

Wire Gauge

-

Ring terminals: Small to medium gauges.

-

Lugs: Medium to very large gauges (battery cables, power lines).

Current Capacity

-

Ring terminals: Suitable for light/medium electrical loads.

-

Lugs: Designed for high-current, high-power applications.

Installation Methods

-

Ring terminals: Typically simple crimping.

-

Lugs: May require hydraulic crimpers, compression tools, or soldering.

Application Environment

-

Ring terminals: Automotive circuits, small machines, home appliances.

-

Lugs: Factories, power systems, motors, heavy equipment.

Comparison Table: Ring Terminal vs. Lug

| 特徴 | Ring Terminal | Lug |

|---|---|---|

| 意味 | A specific type of terminal with a circular ring end | A general category of heavy-duty cable connectors |

| Typical Usage | Light to medium wiring | Medium to heavy power cables |

| Wire Gauge | Small to medium | Medium to very large |

| Connection End | Always a closed ring | Can be ring, spade, or flat pad |

| Installation | Crimping | Crimping, hydraulic crimping, soldering, compression |

| Application Areas | 自動車, control panels, small machines | Battery cables, motors, industrial power lines |

Where Should You Use Each Connector?

Use Ring Terminals When:

-

You need a secure, vibration-resistant connection

-

You are working with small or medium wires

-

You are wiring cars, motorcycles, small equipment, or control panels

-

The current load is moderate

Use Lugs When:

-

You must connect large cables

-

The system carries high voltage or high current

-

You need strong mechanical support and heat resistance

-

The installation is industrial, automotive battery, or power distribution related

Choosing the correct connector ensures not just performance, but also safety and reliability in demanding environments.

Tips for Selecting the Right Connector

-

Match the wire gauge: Using the wrong size can lead to overheating or loose connections.

-

Check current ratings: Higher loads require heavy-duty lugs.

-

Choose the correct material: Tinned copper offers corrosion resistance and better conductivity.

-

Use proper tools: Standard crimpers for ring terminals; hydraulic tools for large lugs.

-

Consider the environment: For vibration-heavy environments, ring terminals offer superior security.

結論

Ring terminals and lugs are both essential components in electrical wiring, but they serve different roles.

-

Ring terminals are ideal for light- to medium-duty applications and provide a secure, vibration-resistant connection.

-

Lugs are engineered for heavy-duty industrial environments where high current, large cables, and strong mechanical reliability are required.

By understanding the structural and functional differences between these two connectors, you can choose the right option for your wiring project—ensuring safety, パフォーマンス, そして長期的な信頼性.

よくある質問

Are ring terminals and lugs the same thing?

No. Ring terminals are a specific type of terminal used for small to medium wires, while lugs are heavy-duty connectors designed for large cables and high-current applications.

When should I use a ring terminal instead of a lug?

Use a ring terminal when working with light to medium wiring, such as automotive circuits, control panels, and grounding points where vibration resistance is important.

What types of lugs are available?

Lugs come in various types including ring lugs, spade lugs, tubular lugs, and compression lugs. They differ by end shape, installation method, and current-carrying capacity.

Can ring terminals handle high current?

Generally, no. Ring terminals are designed for smaller wires and moderate current. For high-current applications—such as battery cables or industrial power lines—lugs are the safer choice.

How do I choose the right size of ring terminal or lug?

Match the connector to both the wire gauge and the bolt size. Also consider factors like current load, material (copper or tinned copper), and whether the environment requires heavy-duty or vibration-resistant connections.