In the medical industry, connectors are far more than simple interconnection components. They are critical elements that directly impact patient safety, device reliability, regulatory compliance, and long-term performance. From diagnostic imaging systems to wearable monitoring devices, medical connectors must meet some of the most demanding electrical, mechanical, and environmental requirements of any industry.

As a professional manufacturer of medical connectors and cable assemblies, we understand that selecting the right connector solution is not only a technical decision, but also a strategic one. This article provides an in-depth, manufacturer-level overview of medical connector types, regulatory requirements, 재료, environmental challenges, and future trends, helping medical device designers and OEMs make informed decisions.

The Role of Connectors in Medical Devices

Medical connectors serve as the vital interface between electronic modules, 센서, power supplies, and patient-contact devices. Unlike general industrial connectors, medical connectors must deliver:

-

Stable signal transmission for low-level physiological signals

-

High reliability over thousands of mating cycles

-

Compatibility with sterilization and cleaning processes

-

Compliance with strict international medical standards

Although many connector platforms are shared with aerospace, 산업 자동화, and military markets, medical applications impose unique regulatory and usability constraints that significantly influence connector design and manufacturing.

Regulatory Framework for Medical Connectors

FDA Medical Device Classification

In the United States, the FDA classifies medical devices into three categories based on risk:

-

Class I – Low risk (basic monitoring devices)

-

Class II – Moderate risk (diagnostic and therapeutic equipment)

-

Class III – High risk (life-supporting or implantable devices)

The higher the classification, the stricter the requirements for connector reliability, traceability, and risk control.

Quality System and Manufacturing Compliance

Medical connector manufacturing must align with FDA 21 CFR 820, which governs quality system regulations. This requires controlled production processes, documented inspections, and full traceability of materials and components.

International Standards and Risk Management

Medical electrical equipment must comply with IEC 60601-1, a foundational standard for electrical safety and performance. In addition, ISO 14971 risk management plays a critical role, requiring manufacturers to evaluate risks associated with connector materials, insulation, spacing, 장기적인 신뢰성.

While the final medical device manufacturer is responsible for certification, connector suppliers must provide compliant designs, 재료, and supporting documentation.

Operational Requirements for Medical Connectors and Cables

Safety and Ease of Use

Patient and operator safety is the top priority. Medical connectors must be easy to operate, even when users are wearing surgical gloves. For this reason, push-pull locking connectors with audible and tactile feedback are widely preferred.

Error Prevention

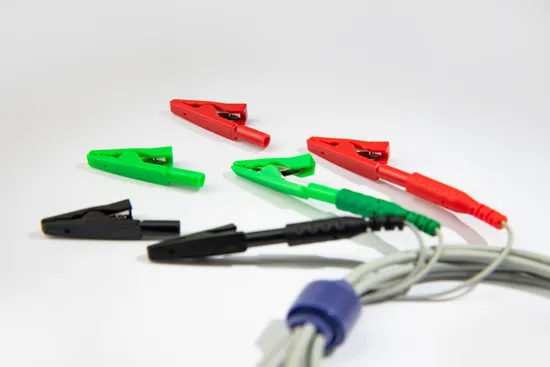

To reduce the risk of misconnection:

-

Color coding is commonly applied

-

Mechanical keying prevents incorrect mating

-

Polarization ensures correct orientation

These features are especially critical in emergency and high-pressure clinical environments.

Electrical Performance and Signal Integrity

Many medical signals, such as ECG or EEG, operate at extremely low voltage levels. Connector contact resistance, shielding effectiveness, and long-term stability are essential to maintain signal accuracy. EMC shielding and controlled impedance designs are often required.

Mating Cycle Durability

While some patient-side connectors are single-use, instrument-side connectors must often withstand up to 10,000 mating cycles, making contact plating quality and mechanical design crucial.

Environmental and Sterilization Challenges

Medical connectors must survive repeated exposure to harsh sterilization methods, 포함:

-

Steam autoclave

-

STERRAD® hydrogen peroxide plasma

-

Ethylene oxide (EtO)

-

Gamma radiation

-

Chemical disinfectants

Reusable connectors are often protected with sealing caps during sterilization, while disposable assemblies are factory-sterilized and packaged.

IP Ratings and Sealing Performance

Ingress protection is essential in clinical and laboratory environments. Medical connectors are commonly required to meet IP65, IP67, or IP68 ratings, ensuring protection against dust, fluids, and cleaning agents.

For example:

-

IP67 connectors provide complete dust protection and withstand temporary water immersion

-

Proper sealing design prevents corrosion, leakage, and electrical failure

Medical Connector Materials: Performance and Biocompatibility

Material selection is a defining factor in medical connector design. High-performance thermoplastics commonly used include:

-

PPSU (Polyphenylsulfone)

-

PSU (Polysulfone)

-

PEI (Polyetherimide)

These materials offer:

-

High continuous temperature resistance

-

Excellent hydrolysis and chemical resistance

-

Stability under repeated sterilization

-

Good electrical insulation properties

-

Resistance to gamma and X-ray radiation

Metal contacts are typically copper alloys with gold or tin plating to ensure conductivity and corrosion resistance.

Trends in Medical Connector Technology

소형화

The growth of portable and home healthcare devices is driving demand for smaller, lighter connectors. 하지만, miniaturization increases the importance of insulation distances, creepage paths, and risk analysis under ISO 14971.

Hybrid and Integrated Connectors

Modern medical systems often require more than electrical connections. Hybrid connectors combining:

-

Electrical signals

-

Fluid lines

-

Fiber optics

are becoming increasingly common, particularly in advanced diagnostic and surgical equipment.

Smart Identification and Custom Assemblies

RFID integration and intelligent cable assemblies help ensure correct device configuration and traceability. Professional manufacturers increasingly deliver custom medical cable and connector assemblies tailored to specific device architectures.

Manufacturer Capabilities and Certifications

Choosing a qualified medical connector manufacturer is essential. Key certifications include:

-

ISO 9001 – Quality management

-

ISO 13485 – Medical device quality systems

-

ISO 14001 – Environmental management

-

IPC/WHMA-A-620 – Cable assembly standards

-

IATF 16949 – Automotive-grade process control

-

UL approvals

These certifications demonstrate a manufacturer’s ability to deliver 일관된 품질, regulatory compliance, 장기적인 신뢰성.

결론: Partnering with the Right Medical Connector Manufacturer

Medical connectors are mission-critical components that directly influence device safety, compliance, and performance. From regulatory requirements and sterilization resistance to material science and miniaturization, every detail matters.

By working with an experienced, certified medical connector manufacturer, medical device OEMs gain not only reliable products, but also engineering support, risk mitigation, and long-term supply stability. As medical technology continues to evolve, high-quality connector solutions will remain a cornerstone of safe, effective, and innovative healthcare systems. 문의하기 자세한 내용은.