Electronic connectors are essential components that enable electrical continuity, signal integrity, and system reliability across countless industries—from automotive and industrial automation to communications, ruimtevaart, and medical technology. Although connector designs vary widely, the core manufacturing process follows a highly structured and controlled workflow. As a precision connector manufacturer, mastering each stage is critical to ensuring performance, long-term durability, and compliance with global quality standards.

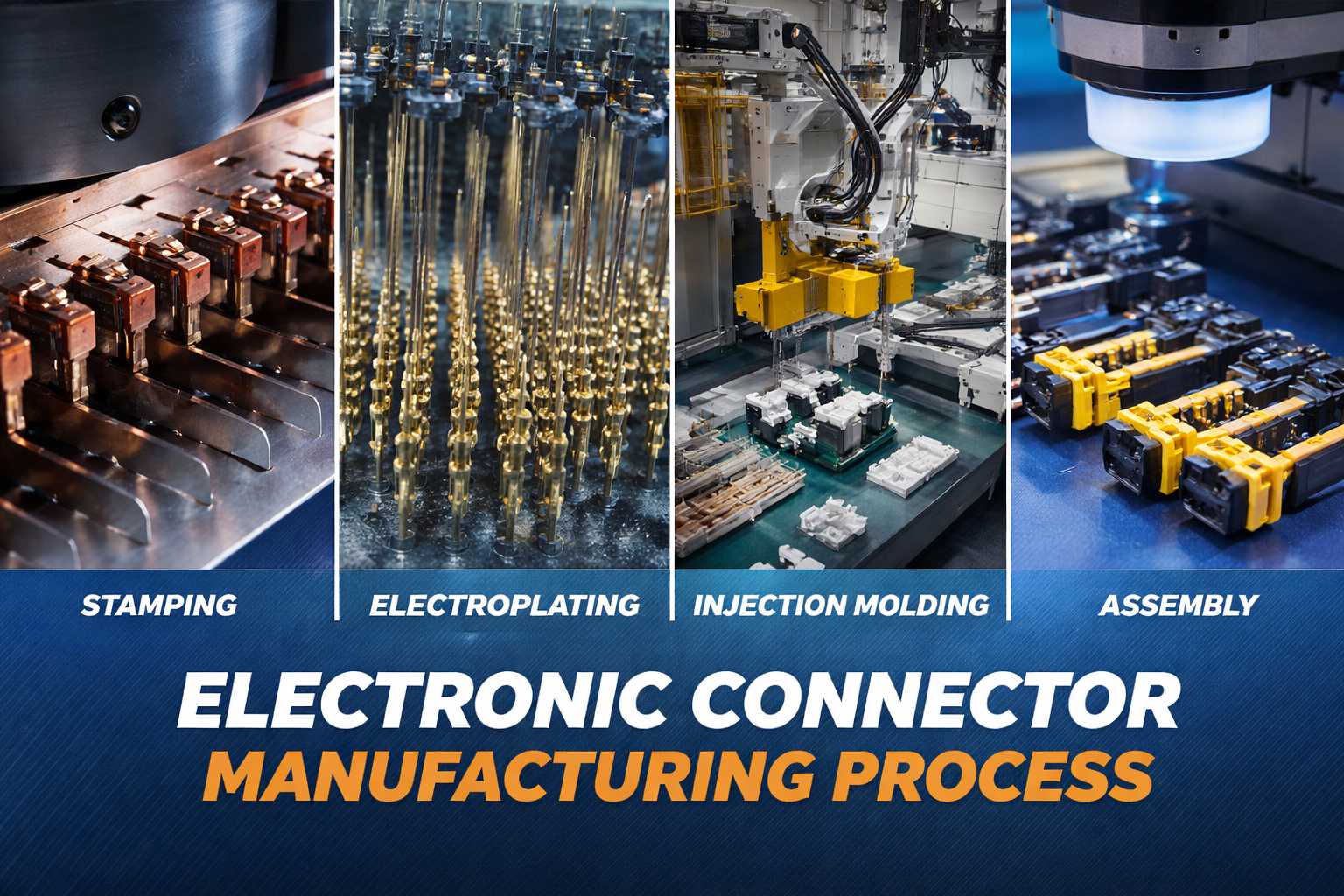

This article provides an in-depth look at the four major stages of connector production—stamping, galvaniseren, spuitgieten, en montage—highlighting the technical requirements, quality challenges, and advanced inspection methods that support high-reliability connector manufacturing.

Precision Stamping: Forming the Foundation of Connector Performance

Connector manufacturing begins with the creation of metal contacts, which serve as the conductive pathways for electrical transmission. These contacts must meet strict dimensional tolerances to ensure proper mating, low resistance, and long-term stability.

High-Speed Stamping Technology

Large high-speed stamping presses are used to transform copper alloy or brass strip into precision-formed contact terminals. The metal strip is fed continuously from a coil, stamped at high frequency, and wound onto reels for downstream processing.

Typical Stamping Challenges

Even with advanced equipment, several issues may arise:

-

Bent or distorted pins

-

Cracks or fractures caused by metal fatigue

-

Burrs or dimensional deviations from worn tooling

-

Misfeeds and pitch errors in the feed system

Because stamped terminals determine the electrical performance and reliability of the final connector, early-stage quality control is essential. High-resolution camera systems, inline measurement sensors, and tool wear monitoring technologies are widely used to maintain stamping consistency.

Electroplating: Enhancing Conductivity, Corrosion Resistance & Durability

Once contacts are stamped, they undergo electroplating to achieve the surface characteristics required for their end applications.

Why Electroplating Matters

Plating improves:

-

Electrical conductivity

-

Corrosion resistance

-

Wear resistance during mating cycles

-

Solderability and bonding performance

-

Signal integrity for high-frequency applications

Common plating materials include tin, nickel, silver, and gold. High-reliability connectors may require multilayer plating structures.

Inspection Challenges in Electroplating

The irregular geometry and reflective surface of connector pins make visual inspection complex. Manufacturers must detect:

-

Micro-scratches

-

Pinholes or porosity

-

Uneven or missing plating

-

Incorrect coating thickness

-

Surface discoloration

-

Inconsistent layer stacking

Traditional monochrome machine vision often struggles due to similar grayscale values between different metals. Advanced systems—such as color vision, multi-angle lighting, or hyperspectral inspection—are increasingly integrated into modern plating lines.

Injection Molding: Creating High-Precision Insulating Housings

The connector housing (also called the insulator or body) is produced during the injection molding stage. This component ensures mechanical alignment, retention, and insulation between contacts.

Injection Molding Process

Molten engineering plastic is injected into a precision mold cavity, rapidly cooled, and ejected to form the housing. Common materials include:

-

PA66 / PA46 (high mechanical strength)

-

PBT (good dimensional stability)

-

LCP (excellent for high-temperature or micro-pitch connectors)

Defects Commonly Detected in Molding

-

Short shots (incomplete filling)

-

Flash around cavities

-

Warping or deformation

-

Blocked terminal cavities

-

Surface blemishes

Backlight machine vision makes it easier to detect incompletely molded areas and ensure that mating interfaces, locking structures, and terminal channels meet engineering specifications.

Final Assembly: High-Precision Pin Insertion and Connector Integration

Assembly is the most complex stage of connector manufacturing, requiring precise alignment of metal contacts into molded housings. Any deviation can lead to electrical failure or poor mating quality.

Assembly Methods

-

Single-pin insertion (ideal for specialized or low-volume connectors)

-

Multi-pin group insertion (efficient for high-density connectors)

Critical Inspections During Assembly

Manufacturers must verify:

-

No missing pins

-

Correct pin position and depth

-

Accurate terminal spacing

-

Proper retention force

-

Alignment with mating connectors

-

Housing integrity after insertion

Large multi-row or high-pin-count connectors pose additional challenges. To inspect every pin with micron-level precision, manufacturers may use:

-

Multi-camera inspection arrays

-

Automated XY scanning platforms

-

Continuous motion imaging (image stitching)

-

Laser displacement or 3D inspection

These technologies ensure that even connectors exceeding one foot in length with hundreds of terminals meet strict tolerance requirements.

The Importance of Full-Process Quality Control

High-reliability connectors require strict control at every stage. Manufacturers implement:

-

Incoming material verification

-

Tool and mold maintenance programs

-

Inline automated inspections

-

Statistische procesbeheersing (SPC)

-

Final functional and dimensional testing

Compliance with standards such as ISO9001, ISO14001, IATF16949, UL, and IPC-620 ensures that connectors meet global requirements for electrical performance, environmental durability, en betrouwbaarheid.

Conclusie: Precision Manufacturing Enables Reliable Electronic Connectors

The production of electronic connectors is far more complex than it appears. Each stage—stamping, galvaniseren, spuitgieten, and assembly—requires specialized equipment, advanced inspection technologies, and strict process control. As a precision connector manufacturer, ensuring the consistency, betrouwbaarheid, and accuracy of each connector is not only a technical requirement but also a commitment to customers who rely on stable interconnect solutions in mission-critical systems.

By investing in high-precision manufacturing, smart automation, and rigorous quality management, connector manufacturers can deliver products that meet the ever-growing demands of modern electronics, ensuring performance, longevity, and safety across global industries.

Veelgestelde vragen

1. Why is precision stamping so critical in connector manufacturing?

Precision stamping determines the dimensional accuracy, mechanical strength, and electrical performance of connector contacts. Even minor deviations in pin geometry can lead to poor mating, increased contact resistance, or premature failure, making early-stage stamping control essential.

2. What materials are commonly used for connector contacts?

Connector contacts are typically made from copper alloys, brass, phosphor bronze, or beryllium copper. These materials provide an optimal balance of conductivity, spring force, formability, en betrouwbaarheid op lange termijn.

3. How does electroplating affect connector performance?

Electroplating enhances conductivity, corrosiebestendigheid, wear life, and solderability. Proper plating thickness and uniformity are crucial for maintaining low contact resistance, stable signal transmission, and reliable performance over repeated mating cycles.

4. What are the most common quality issues in connector electroplating?

Common plating defects include uneven coating thickness, pinholes, scratches, poor adhesion, oxidation, and incorrect multilayer stacking. Advanced optical inspection and thickness measurement systems are required to detect these issues reliably.

5. Why is injection molding accuracy important for connector housings?

The housing controls contact alignment, insulation spacing, and mechanical retention. Any molding defect—such as warping, flash, or blocked cavities—can prevent proper pin insertion, reduce mating accuracy, or compromise electrical safety.

6. What challenges arise during the final assembly of connectors?

Final assembly must ensure correct pin count, depth, spacing, and retention force. High-pin-count or long connectors require extremely precise alignment, and missing or misaligned pins can result in functional failure or mating damage.

7. How do manufacturers ensure consistent quality across large production volumes?

Manufacturers rely on inline automated inspection, statistical process control (SPC), regular tool maintenance, and standardized work instructions. These systems help maintain consistent quality even in high-volume, high-speed production environments.

8. What quality standards apply to electronic connector manufacturing?

Electronic connectors are commonly manufactured under ISO9001, ISO14001, IATF16949, UL, and IPC-620 standards. These certifications ensure compliance with global requirements for electrical performance, environmental protection, and manufacturing reliability.