In both electrical and electronic systems, terminals play a crucial role in facilitating connections between different components. Whether it’s a power connection in a circuit, a data transfer, or even a communication link in payment terminals, understanding the different types of terminals is vital for ensuring optimal functionality, reliability, e segurança. Terminals are available in various forms, each designed to cater to specific needs in wiring and connectivity. This article explores the various types of terminals, their uses, and considerations for choosing the right type for different applications.

Electrical Terminals

Electrical terminals are critical components in any electrical system, as they establish secure connections between wires, devices, and other electrical equipment. These connectors ensure the efficient flow of electricity and signal transmission, which is essential in maintaining the proper function of electrical circuits. Electrical terminals come in various shapes, sizes, and materials, with each type suited for specific applications.

The primary purpose of electrical terminals is to facilitate reliable and safe electrical connections. Without proper terminals, the connection between electrical components would be prone to issues such as loose connections, short circuits, overheating, and even failure of the system. Because of their importance, choosing the right type of terminal for a given application is essential to the performance and longevity of the system.

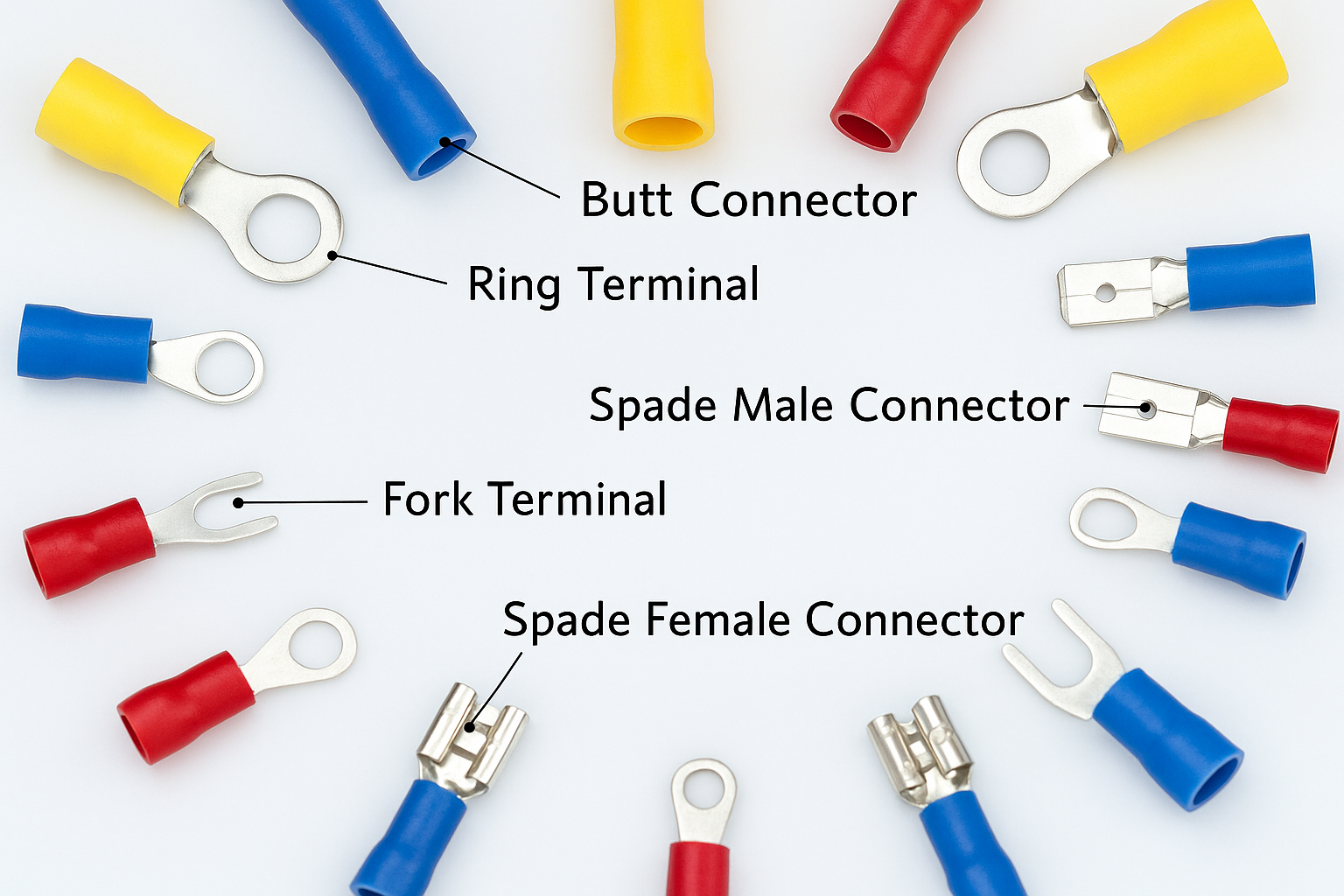

Types of Electrical Terminals:

- Ring Terminals:

Ring terminals, also known as closed-loop terminals, have a circular ring shape at one end. This design allows them to be securely fastened to a screw or stud, ensuring a stable connection. The crimped end of the ring terminal is attached to the wire, while the ring itself is threaded onto a bolt or screw, often with a nut to secure the connection. Ring terminals are commonly used in automotive, industrial, and marine applications, where vibrations or movement could potentially cause other types of connections to loosen. Their strong connection makes them suitable for high-current applications where stability is critical. - Spade Terminals:

Spade terminals are similar to ring terminals, but instead of a circular loop, they feature a forked shape. The fork design allows for easy attachment and detachment, making them a good choice when connections need to be made and broken regularly. Spade terminals are commonly used in situations where space is a concern, and they are easier to insert and remove without needing special tools like screwdrivers or pliers. These terminals are often used in circuit boards, power distribution systems, and electronics where frequent maintenance or modifications are required. - Bullet Terminals:

Bullet terminals are a type of connector that is designed for quick and easy attachment and detachment. They consist of a male and female part that “snap” together, forming a secure connection. Bullet connectors are commonly used in automotive wiring and other systems where components may need to be disconnected and reconnected regularly, such as in portable electronic devices or mobile machinery. Their design is compact, allowing them to fit in smaller spaces, and they are often used for lower voltage applications. - Butt Connectors:

Butt connectors are used to join two wires together in a side-by-side manner. These terminals are particularly useful when splicing two wires of the same gauge. A typical butt connector has a hollow, cylindrical shape, and the wire is inserted into either end before being crimped into place. This type of terminal is widely used for wiring in automotive and home electrical systems where two wires need to be connected without the need for additional connectors or junction blocks. - Flag Terminals:

Flag terminals are specially designed for applications with limited space. The “flag” shape allows the terminal to be attached in tight or hard-to-reach places where conventional connectors would be impractical. These are often used in circuit boards and electronic devices that require compact components. Flag terminals are ideal for situations where wires need to be connected to very small or densely packed equipment, such as in telecom or networking systems. - Insulated vs. Non-Insulated Terminals:

Electrical terminals are available in both insulatede non-insulated Insulated terminals are coated with a protective layer, usually plastic or rubber, that prevents the wire from coming into contact with other conductors or surfaces that could cause short circuits. These types of terminals are ideal for environments where the terminal might be exposed to moisture, vibrations, or harsh chemicals. On the other hand, non-insulated terminals are used in applications where insulation is not required, such as in low-voltage or controlled environments. Non-insulated terminals are generally more compact and allow for easier heat dissipation, which can be beneficial in high-power or high-temperature applications.

Materials Used for Electrical Terminals

The materials used to manufacture electrical terminals are just as important as the terminal type itself. The choice of material directly impacts the performance, durability, and reliability of the terminal. The most commonly used materials for electrical terminals include:

- Copper:

Copper is the most widely used material for electrical terminals due to its excellent conductivity and durability. It allows for efficient current flow and is highly resistant to corrosion, especially when plated with a thin layer of tin or nickel. Copper terminals are commonly used in low- and high-voltage systems, as well as in applications that require high conductivity, such as in power distribution and electrical wiring in homes and industrial buildings. - Phosphor copper:

Phosphor copper is often chosen for components like spade terminals, ring terminals, and other electrical connectors where both electrical performance and mechanical durability are crucial. Its versatility, combined with its conductive properties and corrosion resistance, makes phosphor copper an excellent choice for terminals that need to deliver high performance while withstanding environmental challenges over time. - Brass:

Brass terminals are used in many applications where copper is not the best choice. Brass is more resistant to corrosion and is typically used in environments where terminals are exposed to moisture, such as marine applications. Brass has a lower conductivity than copper, but its durability and ability to withstand corrosion make it an ideal material for specific use cases. - Aluminum:

Aluminum is often used in terminal construction for its lightweight nature and corrosion resistance, especially in power transmission lines and high-voltage systems. However, aluminum terminals require careful attention to detail during installation because of the metal’s tendency to oxidize, which can hinder electrical performance. Special aluminum connectors are often used to prevent this issue and ensure a reliable connection. - Steel:

Steel is sometimes used for terminals that need to withstand mechanical stress, particularly in industrial applications. Steel is typically not used for its electrical conductivity but rather for its strength and ability to endure harsh mechanical conditions.

Specialized Terminal Types

Some terminals are designed for specific applications that require specialized features. These are usually found in advanced electronics or high-performance settings.

xr:d:DAFY1vPBQog:10,j:4387685194,t:23051012

Types of Specialized Terminals:

- Push-In Terminals: These terminals are used where easy wire insertion is needed. The wire is simply pushed into the terminal, making a secure connection. They are common in circuit boards and high-density wiring environments.

- Quick Connect Terminals: Quick connect terminals allow for easy and fast installation, typically using a “snap-on” mechanism. These are often used in automotive applications or in situations where components need to be frequently disconnected and reconnected.

- Wire Wrap Terminals: Used in wire-wrapping applications, these terminals provide a solid connection for low-voltage, low-current circuits, commonly seen in prototyping or specialized electronics.

Choosing the Right Terminal

Selecting the right electrical terminal is crucial to the overall performance and safety of the system. When choosing a terminal, several factors need to be considered, incluindo:

- Wire Gauge:

Ensure the terminal matches the gauge of the wire being used. A terminal that is too large for a wire will not make a secure connection, while a terminal that is too small will not accommodate the wire, leading to an unreliable connection. - Current and Voltage Requirements: Different terminals are rated for various current and voltage levels. Choosing the wrong terminal can lead to electrical hazards or performance issues.

- Environmental Factors: Terminals used in outdoor or harsh environments may need to be resistant to moisture, corrosion, or extreme temperatures. In such cases, insulated or sealed terminals are preferred.

- Size and Space Constraints: In tight spaces, smaller terminals like flag or push-in terminals are better suited to ensure a secure connection without compromising functionality.

- Ease of Installation:

Consider how easy the terminal is to install, especially for systems that require frequent maintenance or modification. Crimp connectors and quick-connect terminals are ideal for quick, secure connections.

Conclusão

Electrical terminals are indispensable for maintaining safe and efficient electrical systems. With various types designed for different uses, materials, and environmental conditions, selecting the right terminal is critical for the success of your project. Whether it’s a simple residential circuit or a complex industrial system, understanding the different types of terminals and their applications ensures the reliability and longevity of your electrical connections.

Perguntas frequentes

1. What is a electrical terminal in electrical systems?

A terminal is a connection point where wires are attached to electrical components, devices, or other wires. They are used to facilitate the safe and reliable transfer of electrical signals or power, and they come in various designs such as ring, spade, and bullet terminals.

2. What is the difference between a ring terminal and a spade terminal?

Both ring and spade terminals are used for connecting wires to screws or studs. A ring terminal has a circular “ring” at one end that fits over a screw or stud, while a spade terminal has a forked design, making it easier to quickly connect or disconnect from a terminal.

3. What type of terminal is best for outdoor or harsh environments?

For outdoor or harsh environments, terminals that are insulated ou sealed are typically preferred. These terminals are designed to resist moisture, corrosion, and extreme temperatures, ensuring long-term durability in difficult conditions. Some terminals are also coated with weather-resistant materials for added protection.

4. How do push-in terminals differ from other types?

Push-in terminals allow you to insert the wire into the terminal without needing screws or crimping. They are easy to use and are ideal for quick, secure connections in applications where wires need to be frequently connected and disconnected. These terminals are commonly used in circuit boards and high-density wiring environments.

5. What factors should I consider when choosing the right terminal?

When selecting a terminal, you should consider:

- Current and voltage requirements: Ensure the terminal can handle the electrical load.

- Environmental conditions: Choose insulated or sealed terminals for wet, corrosive, or extreme-temperature environments.

- Space constraints: For compact spaces, smaller terminal types like flag or push-in terminals are recommended.

- Ease of installation and maintenance: Some terminals, like quick connect or push-in terminals, are easier to install and remove.

6. What are the advantages of using a quick-connect terminal?

Quick-connect terminals offer a fast and simple connection method. They are ideal for applications that require frequent disconnecting and reconnecting of components. They are commonly used in automotive, industrial, and consumer electronics due to their convenience.

7. What is a flag terminal, and when is it used?

A flag terminal is a type of terminal connector that has a flag-like shape. This design makes it easier to connect in tight spaces where other terminal types, like ring or spade terminals, might be too bulky. Flag terminals are often used in applications with space constraints or in small electronic devices.

8. Can I use a single terminal type for all electrical connections?

While some terminals may be versatile enough for multiple applications, it is always best to select the right terminal for each specific use case. Different terminals are designed for different purposes, and using the wrong terminal type can lead to poor performance, safety issues, or even failure of the electrical system.

9. What are the differences between non-insulated and insulated terminals?

Non-insulated terminals do not have a protective coating around the metal, while insulated terminals are coated with a material like plastic or rubber to prevent electrical shorts and to offer additional protection from environmental factors. Insulated terminals are commonly used in applications where the wire connection is exposed to moisture, heat, or physical wear.

10. Are there specialized terminals for high-voltage applications?

Sim, certain types of terminals are designed specifically for high-voltage or high-current applications. These terminals are made from materials that can handle increased electrical loads and are often designed with robust insulation to protect against the risks associated with high-voltage systems.