What Are Insulated Terminals

Insulated terminals are electrical connectors designed with a protective insulation sleeve that covers the metal conductor. This insulation layer prevents accidental short circuits, reduces the risk of electric shock, and improves overall connection reliability in electrical and electronic systems.

Compared with uninsulated terminals, insulated terminals provide enhanced safety during installation and operation, especially in environments where vibration, nem, or close conductor spacing is present. They are widely used in applications that require secure, long-term electrical connections with additional protection for both operators and equipment.

Key Benefits of Insulated Terminals

Insulated terminals are engineered to improve electrical safety, installation efficiency, and system durability.

-

Enhanced Electrical Safety

The insulation layer minimizes the risk of short circuits and accidental contact with live conductors. -

Reliable Performance in Harsh Conditions

Designed to resist vibration, toz, and moisture, ensuring stable connections over time. -

Improved Installation Efficiency

Pre-insulated design simplifies handling and reduces installation errors. -

Long-Term Connection Stability

Strong mechanical retention combined with stable conductivity supports long service life.

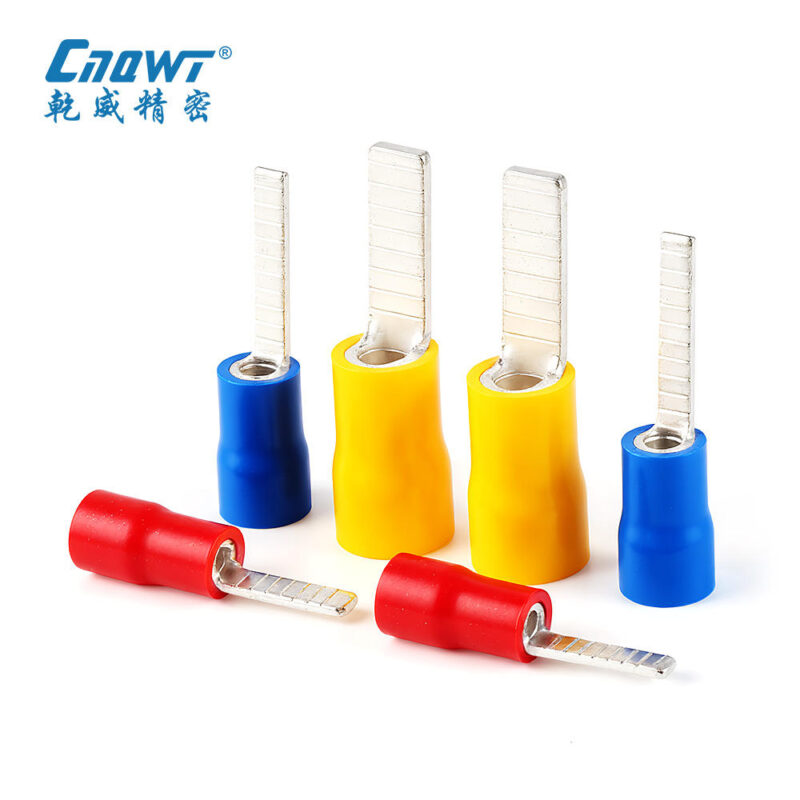

Insulation Types

Selecting the right insulation material is critical to performance and durability. Qianwei offers insulated terminals with different insulation options to match application requirements.

PVC Insulation

PVC insulated terminals are cost-effective and suitable for general-purpose electrical applications. They offer good flexibility and reliable insulation for standard environments.

Nylon Insulation

Nylon insulation provides higher mechanical strength, improved heat resistance, and superior aging performance. It is ideal for automotive, endüstriyel, and high-reliability applications.

Our engineering team can assist in selecting the optimal insulation material based on operating conditions, temperature range, and compliance requirements.

Conductor Material & Plating Options

The performance of insulated terminals depends on both conductor material and surface treatment.

Conductor Materials

-

Copper

-

Brass

-

Phosphor Bronze

These materials ensure excellent electrical conductivity and mechanical strength.

Plating Options

-

Tin Plated (standard)

-

Nickel Plated (optional)

Plating enhances corrosion resistance, improves solderability, and ensures consistent electrical performance in demanding environments.

Technical Specifications

Qianwei insulated terminals are manufactured to meet international electrical and mechanical standards.

-

Wire range: AWG compliant options available

-

Rated voltage and current: Based on terminal design and material

-

Operating temperature range: Suitable for standard and elevated temperature environments

-

Crimp type: Compatible with manual and automated crimping tools

-

Compliance: UL, RoHS, REACH (available upon request)

Detailed technical drawings and specifications are available to support engineering validation and procurement decisions.

Typical Applications

Insulated terminals are widely used across multiple industries where safety and reliability are essential.

-

Automotive wiring harnesses

-

Industrial control and automation systems

-

Home appliances and consumer electronics

-

Power distribution equipment

-

Renewable energy and energy storage systems

Their versatility makes them a trusted solution for both standard and custom electrical assemblies.

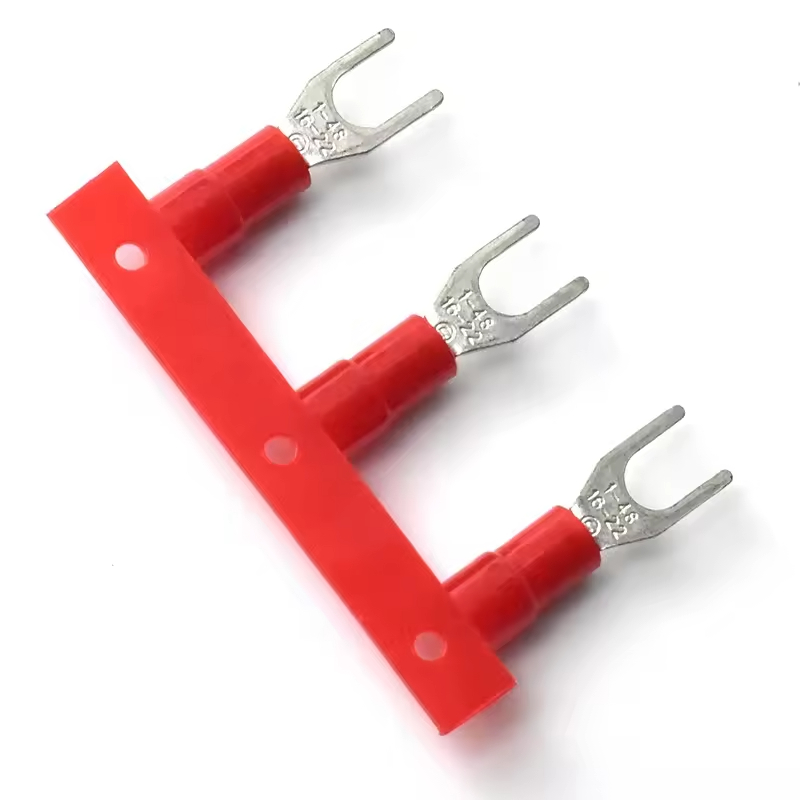

Customization & OEM / ODM Support

Qianwei Precision provides full customization services for insulated terminals to support OEM and ODM projects.

-

Custom dimensions and terminal structures

-

Insulation color and material customization

-

Packaging options: bulk, reel, or automation-ready formats

-

Sample development and drawing confirmation

From concept to mass production, our team works closely with customers to ensure precise technical alignment.

Quality Control & Reliability of Qianwei

Quality consistency is critical in electrical connections. Our insulated terminals undergo strict quality control throughout the production process.

-

Incoming material inspection

-

Crimp pull-out force and conductivity testing

-

Process control for dimensional consistency

-

Batch traceability and reliability verification

This ensures stable performance, high repeatability, and long-term reliability in real-world applications.

Why Choose Qianwei

As a professional insulated terminals manufacturer, Qianwei Precision combines manufacturing expertise with customer-focused service.

-

In-house tooling and precision stamping capabilities

-

Stable mass production with controlled lead times

-

Extensive experience serving global B2B customers

-

Technical support from design to application

We focus on building long-term partnerships by delivering dependable products and responsive support.

SSS

What applications are insulated terminals best suited for?

They are ideal for applications requiring enhanced safety, vibration resistance, and reliable electrical connections.

How do I choose between PVC and nylon insulation?

PVC is suitable for general use, while nylon is recommended for higher temperature and industrial environments.

Are insulated terminals suitable for automated crimping?

Evet. Automation-compatible designs and packaging are available.

Do you support small orders or samples?

Evet. Samples and small batch production are available for evaluation and development.