In electrical and electronic systems, safety and reliability are not optional—they are fundamental requirements. From industrial control panels and power distribution systems to automotive wiring harnesses and renewable energy installations, every electrical connection must be secure, stable, and durable. Among the many components that make this possible, thiết bị đầu cuối điện play a critical but often underestimated role.

Electrical terminals are the foundation of reliable electrical connections. They ensure proper current flow, prevent loose wiring, reduce electrical hazards, and support long-term system performance. Choosing the right terminals—and the right manufacturer—can significantly improve system safety, minimize downtime, and lower maintenance costs.

This article explains how electrical terminals improve safety and reliability, why they are essential in modern electrical systems, and what to consider when selecting terminals for your application.

What Are Electrical Terminals?

Electrical terminals are components designed to securely connect electrical wires to devices, equipment, or other wires. They provide a stable mechanical and electrical interface that ensures consistent current transmission while protecting the connection point.

Unlike bare wire connections, thiết bị đầu cuối điện:

Prevent conductor damage

Ensure uniform contact pressure

Improve conductivity

Simplify installation and maintenance

Electrical terminals come in many forms, including ring terminals, spade terminals, fork terminals, pin terminals, blade terminals, and quick-disconnect terminals. Each type is engineered for specific connection requirements, current ratings, and environmental conditions.

In safety-critical and high-reliability applications, using certified, high-quality electrical terminals is essential.

The Role of Electrical Terminals in Electrical Safety

1. Secure and Stable Connections

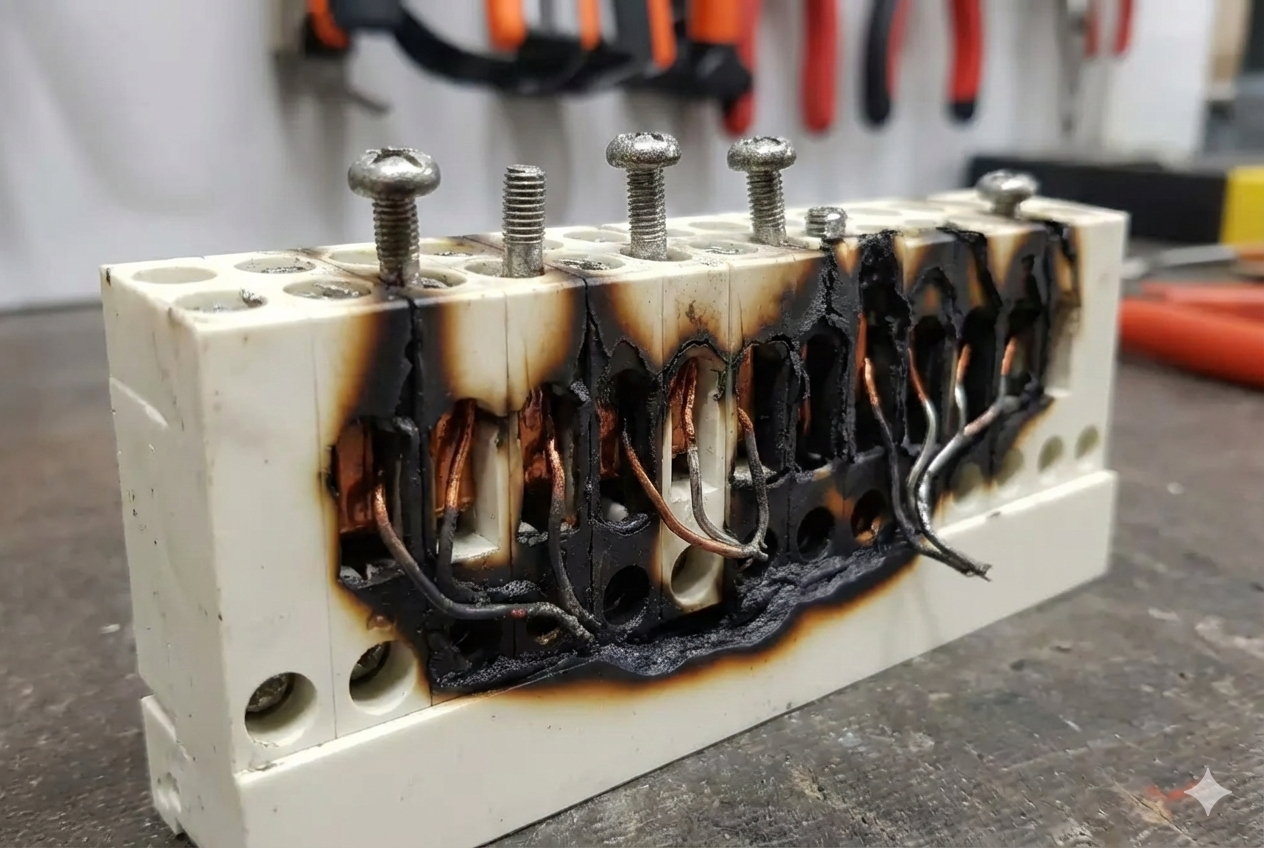

Loose connections are one of the most common causes of electrical failures. They can lead to arcing, overheating, voltage drops, and eventual system breakdown.

Electrical terminals are designed to:

Maintain consistent contact pressure

Prevent wire pull-out

Resist loosening caused by vibration or thermal cycling

Crimped or properly installed terminals create a gas-tight connection between the conductor and the terminal barrel. This eliminates micro-movements and oxidation at the contact point, significantly reducing the risk of sparks or intermittent faults.

2. Protection Against Electrical Overloads

High-quality electrical terminals are rated for specific current and voltage ranges. When selected correctly, they can safely handle load variations without excessive heat generation.

Key safety benefits include:

Reduced resistance at connection points

Lower risk of conductor overheating

Improved protection for downstream equipment

Terminals manufactured with precision-controlled materials and plating ensure stable conductivity even under high-load or continuous-duty conditions. This is especially important in industrial machinery, power distribution panels, and automotive systems.

3. Fire Safety and Compliance with Standards

Electrical fires are often caused by poor connections rather than faulty equipment. Inferior terminals, improper crimping, or mismatched materials can result in heat buildup and insulation failure.

Certified electrical terminals:

Meet national and international safety standards

Are tested for temperature rise, current capacity, and mechanical strength

Use flame-retardant insulation where applicable

Using compliant electrical terminals significantly reduces fire risk and helps systems meet regulatory and insurance requirements.

How Electrical Terminals Improve System Reliability

1. Organized and Repeatable Wiring

In complex electrical systems, wiring clarity and consistency are essential for long-term reliability. Electrical terminals provide standardized connection points that make wiring:

Easier to install

Easier to inspect

Easier to modify or expand

With properly terminated wires, technicians can quickly identify circuits, replace components, or troubleshoot issues without disturbing adjacent connections. This structured approach reduces human error and improves overall system reliability.

2. Consistent Performance in Harsh Environments

Many electrical systems operate under challenging conditions, bao gồm:

Temperature fluctuations

Vibration and mechanical stress

Dust, độ ẩm, and chemicals

High-quality electrical terminals are engineered to perform reliably under these conditions. Features such as corrosion-resistant plating, reinforced insulation, and precise crimp geometries help maintain electrical integrity over time.

This consistency is critical in industries such as manufacturing, transportation, renewable energy, and infrastructure.

3. Reduced Downtime and Maintenance Costs

Connection failures are a leading cause of unplanned downtime. Poor-quality terminals may loosen, corrode, or fail prematurely, resulting in frequent maintenance and costly shutdowns.

Reliable electrical terminals:

Extend system service life

Reduce inspection and repair frequency

Minimize unexpected failures

By investing in well-designed terminals, businesses can improve operational efficiency and reduce total cost of ownership across the lifecycle of their electrical systems.

What to Look for When Choosing Electrical Terminals

To ensure safety and long-term reliability, buyers should evaluate electrical terminals based on:

Material quality (copper alloys, plating options)

Crimp performance and pull-out strength

Compliance with international standards

Manufacturing consistency

Application-specific design support

Working with Độ chính xác của Qianwei-an experienced electrical terminal manufacturer ensures that terminals are not only compliant but optimized for real-world operating conditions.

Conclusion: Why Electrical Terminals Matter More Than Ever

Electrical terminals may be small components, but their impact on system safety and reliability is significant. From preventing loose connections and electrical hazards to ensuring organized, durable wiring, terminals are essential to every well-designed electrical system.

Choosing the right electrical terminals—and sourcing them from a reliable manufacturer—is an investment in system performance, operational stability, and long-term safety. As industries continue to evolve, dependable electrical terminals will remain a cornerstone of safe, đáng tin cậy, and future-ready electrical connectivity.

Câu hỏi thường gặps

1. How do I choose the correct electrical terminal for my application?

Selecting the right electrical terminal depends on several factors, including wire size (AWG or mm²), current and voltage rating, operating environment, and connection method. Matching the terminal specifications precisely to your application ensures optimal safety, conductivity, and long-term reliability.

2. Are crimped terminals safer than soldered connections?

In most industrial and automotive applications, properly crimped terminals are considered safer and more reliable than soldered connections. Crimping creates a gas-tight joint that resists vibration, thermal expansion, and conductor fatigue, whereas soldered joints can crack or loosen over time.

3. What materials are commonly used in high-quality electrical terminals?

High-quality electrical terminals are typically made from copper or copper alloys for excellent conductivity. Surface plating such as tin, nickel, or silver is often applied to improve corrosion resistance, reduce contact resistance, and extend service life in demanding environments.

4. Can electrical terminals be reused after disconnection?

Most crimp-type electrical terminals are designed for single use only. Reusing them can compromise mechanical strength and electrical performance. For safety-critical applications, it is recommended to replace terminals after removal to maintain reliable connections.

5. How do electrical terminals help reduce maintenance and downtime?

Electrical terminals provide stable, standardized connection points that are easy to inspect and service. This reduces troubleshooting time, prevents unexpected connection failures, and minimizes unplanned downtime, especially in complex or high-load electrical systems.

6. Do electrical terminals need to meet specific certifications or standards?

Đúng. Electrical terminals should comply with relevant national and international standards depending on the application and market. Certified terminals ensure consistent quality, predictable performance, and compliance with safety regulations required in industrial and commercial systems.

7. What happens if the wrong terminal size is used?

Using an incorrect terminal size can result in poor crimping, increased resistance, overheating, or wire pull-out. These issues significantly increase the risk of electrical failure and safety hazards. Always ensure the terminal size matches the conductor and application requirements.

8. Are insulated terminals always necessary?

Insulated terminals are recommended in applications where there is a risk of accidental contact, short circuits, or exposure to live components. While not always mandatory, insulated terminals enhance safety and are widely used in control panels, appliances, and confined electrical enclosures.