In today’s increasingly electrified world, wiring harnesses form the backbone of modern electrical and electronic systems. From vehicles and industrial automation to medical devices and energy equipment, wiring harness assemblies ensure power and signals are transmitted safely, efficiently, and reliably.

As a professional wiring harness manufacturer, we understand that a well-engineered harness is far more than a bundle of wires. It is a carefully designed system that directly affects product performance, safety, assembly efficiency, and long-term reliability. This article provides a comprehensive, manufacturer-level overview of wiring harnesses, their functions, materials, applications, and the value of customized solutions.

What Is a Wiring Harness?

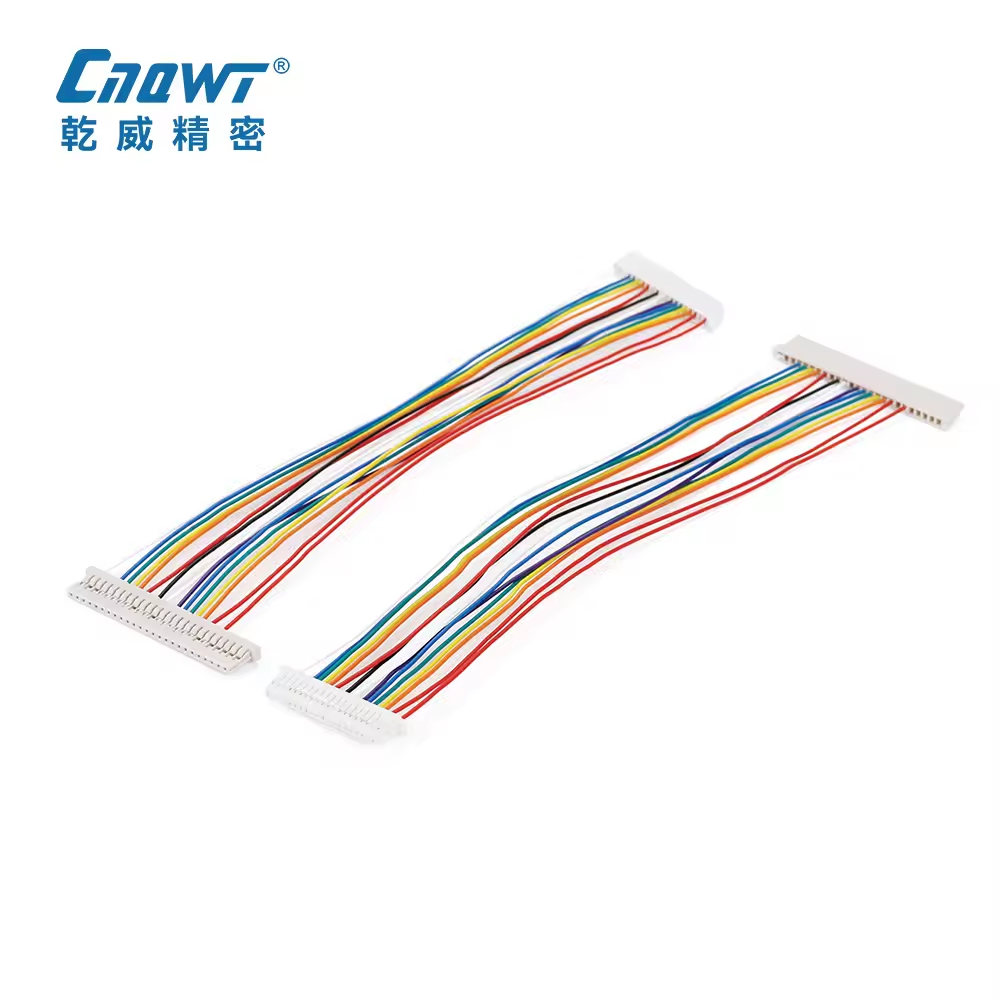

A wiring harness is an organized assembly of electrical wires, cables, connectors, and terminals designed to transmit power and signals within a device or system. Rather than routing individual wires separately, a harness integrates multiple conductors into a single structured unit, allowing for faster installation, improved reliability, and consistent performance.

From a manufacturing perspective, wiring harnesses are engineered to meet precise electrical, mechanical, and environmental requirements. Each harness is designed to fit seamlessly into the customer’s product architecture, often navigating tight spaces, moving components, and harsh operating conditions.

Key Functions of a Wiring Harness

The primary role of a wiring harness extends well beyond electrical connectivity. Professionally manufactured harness assemblies deliver multiple critical functions:

-

Electrical Transmission: Reliable delivery of power, control signals, and data between system components

-

Mechanical Protection: Safeguarding conductors from vibration, abrasion, bending, and impact

-

Environmental Resistance: Protection against heat, moisture, chemicals, dust, and corrosion

-

Installation Efficiency: Pre-assembled layouts reduce wiring errors and assembly time

-

System Reliability: Secure routing and strain relief minimize failures over the product’s life cycle

In demanding industries, these functions are essential to maintaining consistent system performance.

Types of Wiring Harnesses

Wiring harness designs vary depending on application, operating environment, and performance requirements. Common harness types include:

Engine Wiring Harnesses

Designed for high-temperature and high-vibration environments, engine harnesses must withstand oils, fuels, and continuous thermal cycling while maintaining stable electrical connections.

Dashboard and Control Harnesses

Used in vehicles and equipment control panels, these harnesses prioritize compact routing, flexibility, and clean organization within limited space.

Battery Cable Harnesses

Engineered for high-current transmission, battery harnesses use heavy-gauge conductors and reinforced insulation to ensure safe and efficient power delivery.

Sensor and Signal Harnesses

Critical in medical devices, automation, and monitoring systems, sensor harnesses are optimized for low signal loss, EMI resistance, and precision data transmission.

Custom Wiring Harnesses

OEM-specific harnesses tailored to unique layouts, connectors, certifications, and environmental requirements across automotive, industrial, agricultural, and energy sectors.

Materials Used in Wiring Harnesses

Material selection plays a decisive role in harness performance and longevity. Manufacturers carefully choose each component based on electrical load, operating conditions, and regulatory compliance.

Conductors

Copper remains the industry standard due to its excellent conductivity and flexibility. Aluminum may be used where weight reduction is a priority.

Insulation Materials

Common insulation options include PVC, XLPE, and fluoropolymers such as PTFE, selected for heat resistance, chemical stability, and durability.

Connectors and Terminals

Manufactured from brass or copper alloys with tin, nickel, or gold plating, connectors ensure reliable mating, corrosion resistance, and long service life.

Protective Sleeving and Looms

Braided sleeving, corrugated conduit, and heat shrink tubing protect harnesses from mechanical wear and environmental exposure.

Identification and Fastening

Labels, tapes, clips, and ties maintain routing accuracy, simplify installation, and support maintenance and traceability.

Common Applications of Wiring Harnesses

Wiring harness assemblies are integral to a wide range of industries:

-

Automotive & Transportation: Lighting, sensors, infotainment, powertrain, and safety systems

-

Industrial Automation: Robotics, machinery, control cabinets, and factory equipment

-

Medical Devices: Imaging systems, diagnostic equipment, patient monitoring devices

-

Energy & Power Systems: Generators, solar inverters, battery storage, and backup systems

-

Agricultural & Off-Road Equipment: Tractors, harvesters, construction and utility vehicles

Each application demands specific performance, compliance, and durability standards.

Benefits of Professionally Manufactured Wiring Harnesses

From an OEM manufacturing standpoint, wiring harnesses deliver measurable advantages:

-

Improved system organization and cleaner layouts

-

Reduced assembly time and labor costs

-

Lower risk of wiring errors and electrical faults

-

Enhanced safety and mechanical protection

-

Optimized use of space in compact designs

-

Consistent quality across high-volume production

These benefits directly translate into better product reliability and reduced total cost of ownership.

Custom Wiring Harness Solutions for OEMs

Standard harnesses cannot meet every requirement. That’s why leading manufacturers focus on custom wiring harness development, supporting customers from concept to production.

This process includes:

-

Early-stage design collaboration

-

Electrical and mechanical engineering support

-

Material and connector selection

-

Prototyping and validation testing

-

Scalable production for low-volume or mass manufacturing

Custom solutions ensure harnesses integrate seamlessly into the final product while meeting regulatory and performance demands.

Choosing the Right Wiring Harness Manufacturer

Selecting the right manufacturing partner is critical. Key factors include:

-

Proven engineering and design capabilities

-

Advanced wire processing and assembly technology

-

Strict quality control and testing procedures

-

Industry certifications (ISO, UL, IPC, IATF, etc.)

-

Long-term production consistency and supply reliability

A qualified manufacturer does more than produce harnesses—they help optimize product performance and reduce risk.

Conclusion: Wiring Harnesses as the Backbone of Electrical Systems

Wiring harnesses are fundamental to modern electrical systems, enabling safe, efficient, and reliable operation across industries. As products become more complex and performance expectations rise, the importance of professionally engineered harness assemblies continues to grow.

By partnering with an experienced wiring harness manufacturer, OEMs gain access to technical expertise, high-quality materials, and customized solutions designed for long-term success. In every application, a well-designed wiring harness is not just a component—it is a critical foundation for performance, safety, and reliability. Contact us for more information.

FAQ

1. What is the difference between a wiring harness and a cable assembly?

While the terms are often used interchangeably, a wiring harness is typically a bundle of individual wires or cables bound together by an outer sheath or ties to organize a system.1 A cable assembly is generally a more ruggedized collection of wires encased in a heavy-duty outer sleeve (like heat-shrink or rubber) designed for extreme environments and more intense mechanical stress.

2. Why is “strain relief” so important in harness design?

Strain relief protects the connection point where the wire meets the terminal or connector.3 Without proper strain relief, vibration or manual pulling can cause the wire to fatigue and break or pull out of the connector, leading to system failure.4 Manufacturers use specialized backshells, overmolding, or specific routing techniques to ensure long-term durability.

3. How do you protect a wiring harness from Electromagnetic Interference (EMI)?

For signal-sensitive applications like medical devices or automotive sensors, manufacturers use shielded cables, twisted-pair wiring, or specialized metallic braiding/foil.6 These materials block external electrical “noise” from disrupting the data being transmitted through the harness.

4. Can you replace a single wire within a completed wiring harness?

In most professionally manufactured harnesses, individual wire replacement is difficult once the unit is bundled, taped, or sleeved. However, high-quality designs often include “service loops” or modular connectors that allow for easier maintenance.7 For critical systems, it is usually more reliable and cost-effective to replace the entire branch or harness to ensure factory-level integrity.

5. What testing procedures do wiring harnesses undergo before shipping?

Standard quality control includes:

-

Continuity Testing: Ensuring every wire reaches its correct destination.

-

Hipot (High Potential) Testing: Checking for insulation breakdowns or short circuits.

-

Pull-Force Testing: Verifying that terminals are crimped securely to the wires.

-

Visual Inspection: Checking for correct labeling, routing, and connector orientation.

6. Why is UL or IPC-WHMA-A-620 certification important?

These certifications ensure the manufacturer follows global standards for materials and workmanship. Specifically, IPC-WHMA-A-620 is the industry standard for the acceptance of cable and wire harness assemblies, guaranteeing that crimps, solders, and bundles meet rigorous safety and performance benchmarks.

7. How does material selection affect the “flex life” of a harness?

If a harness is used in a robotic arm or a vehicle door, it undergoes constant bending. Manufacturers use high-flex stranding (more thin strands of copper rather than fewer thick ones) and flexible insulation like silicone or specialized PVC to prevent the wires from cracking or hardening over time.

8. What information is needed to request a custom wiring harness quote?

To provide an accurate quote, a manufacturer typically requires:

-

A detailed drawing or schematic.

-

A Bill of Materials (BOM) specifying connectors, wire gauges, and insulation types.

-

The intended environment (temperature range, exposure to chemicals/moisture).

-

Expected production volume and any required certifications (e.g., IATF 16949 for automotive).