14+ Years Focused on Custom Terminals & Connectors

Built by Engineers. Manufactured for Reliability.

- Dedicated terminal & connector factory

- Fast lead time with stable mass production

- Direct engineer-to-engineer technical support

- ISO-certified manufacturing, global compliance

- From prototype to volume production

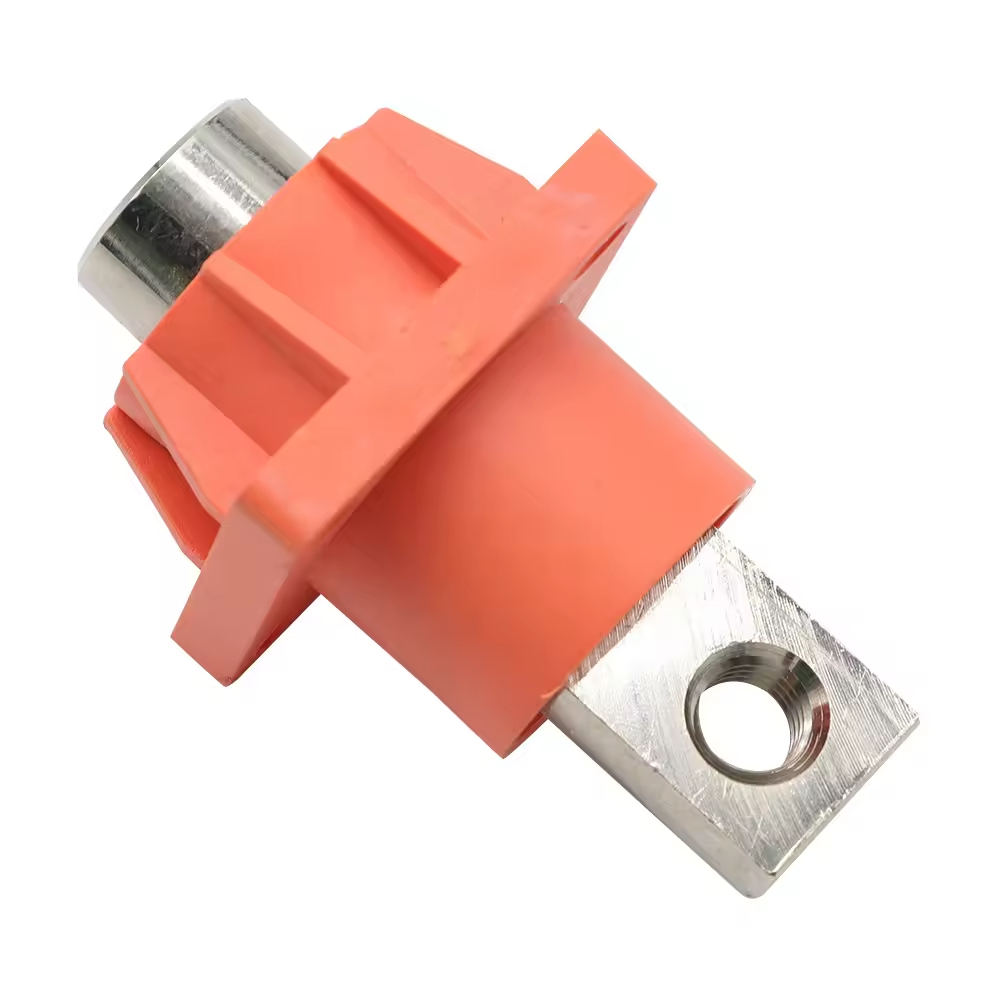

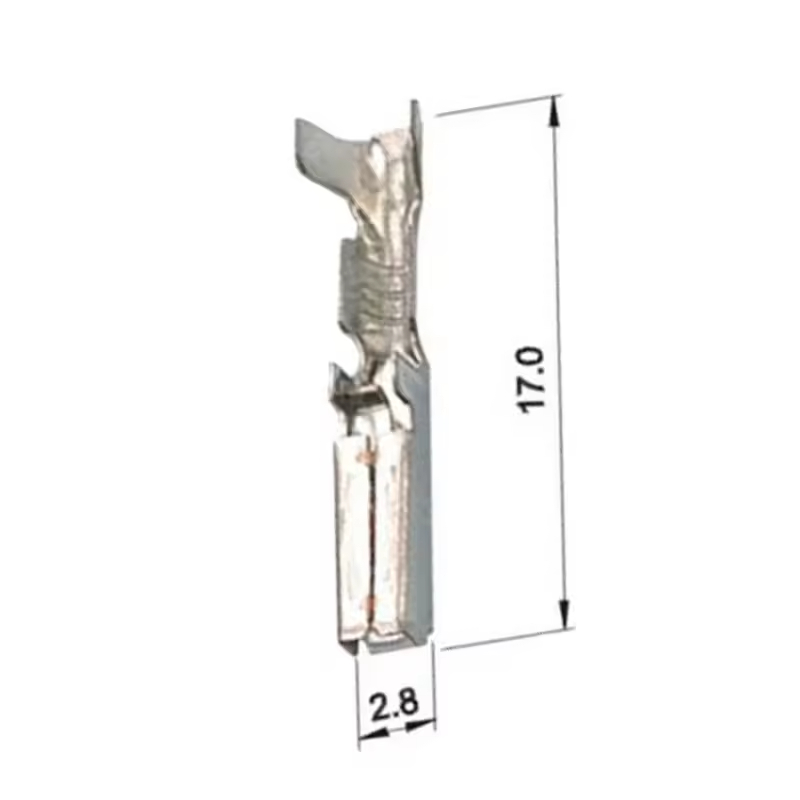

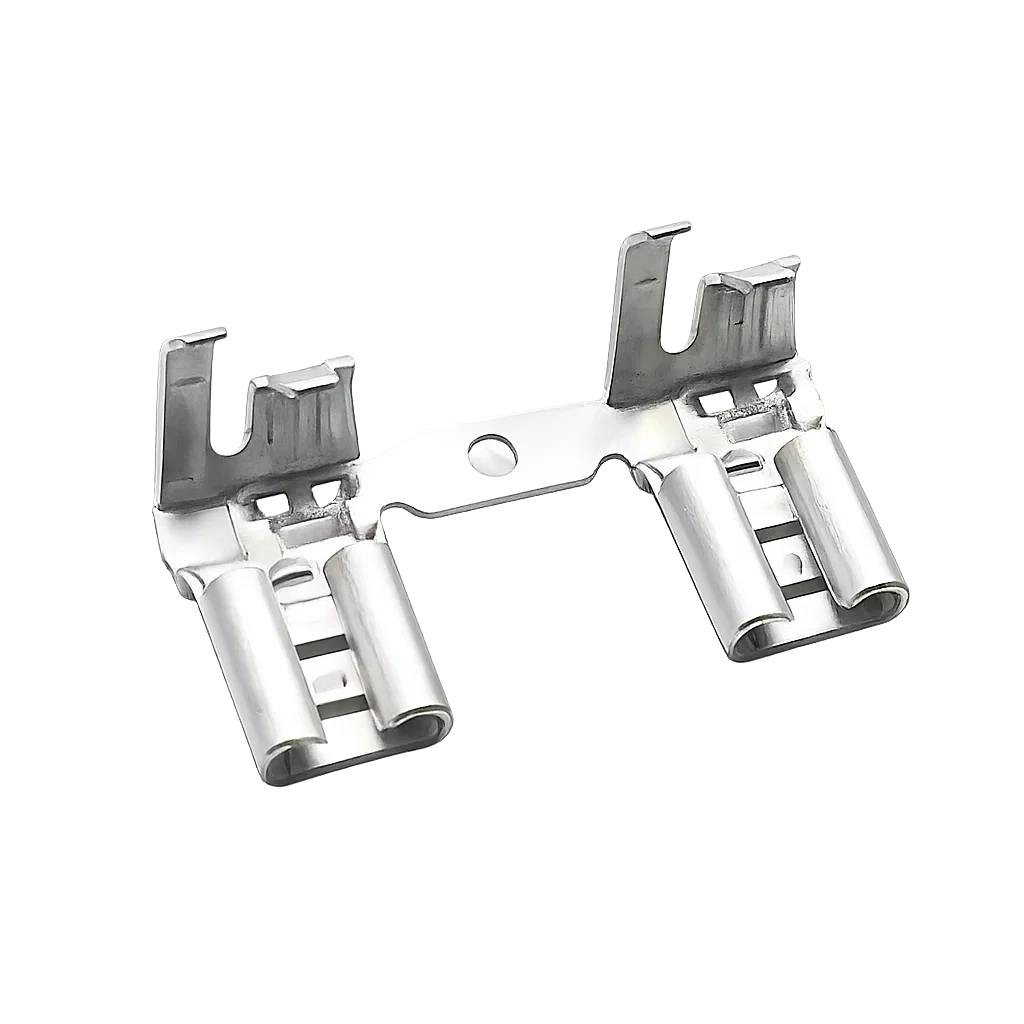

Our Terminal Solutions

QW Precision is a China-based manufacturer specializing in custom electrical terminals, connectors, and cable assemblies. We support OEM and ODM projects for automotive, EV, energy storage, and industrial applications, with low MOQ and fast tooling support.

Custom Solutions

A wide range of technical demands may result in your inability to find the perfect off-the-shelf solution. At Qianwei Precision, we utilize advanced inspection equipment and technology to address your unique requirements.

Industries & Applications

With over 10 years of experience, as a manufacturer of terminals, connectors, injection molding, stamping and wire harness assembly, our mission is to continuously provide customers with high-quality services.

What does Qianwei Precision do?

Guangdong Qianwei Precision Connector Co., Ltd. was established in 2012, we are manufacturer of connector terminals, professional in different kinds of wire terminals, which is widely used in new energy, household appliances ,automotive, computer, communication industry, etc. Qianwei has more than ten years experience in precision wire connector and metal stamping industry, our company is a professional manufacturer of different kinds of mold design and precision connector. Also, as a stable supplier of Tyco, Midea, Haier, Gree, BYD, Jianghuai, Qianwei has four workshops, including high speed stamping, plastic injection molding, mold manufacturing and cable assembly, which has achieved high automation and lean in manufacturing, so our products always lead the market trend.

Our Advatanges

107 production machines

46 quality inspection personnel

Lead time: terminal 1-3 weeks, connector 2-4weeks

Raw material sourcing with a reliable quality management certification

Factory automation rate exceed 98%

Customized terminal and connector R&D one-stop solution

Our Partners

What Our Customer Say

Qianwei Precision are the best terminals. They are heavy duty, built very well, and since they are coated, they are great for automotive and marine use compared to raw copper. They don't oxidize or corrode. They even come with pretty decent heat shrink.

The quality of the sheilding and the material used on the actual terminal is astounding! We use these in car audio and elctrical applications and they are perfectly sized, have a perfect electrical connection, and the heat shrink holds wonderfly!

These battery cable ring lugs are well manufactured and supplied with color-coded heat shrink tubing to clearly identify positive and negative cables. They crimp smoothly, provide a secure hold, and offer excellent value for the price.

Qianwei Precision’s terminals and connectors meet our electrical and mechanical requirements precisely. The products show excellent crimp performance, dimensional consistency, and long-term reliability in real applications.

Qianwei's terminals are exceptionally well made and designed for heavy-duty applications. Once crimped, the connection is mechanically secure and electrically stable, making these lugs a cost-effective solution for professional installations.

Send us an inquiry

We offer you one-stop customized connector and wire solutions.

FAQ

Qianwei Precision specializes in the design and manufacturing of electrical terminals, precision connectors, and customized cable & connector solutions. Our product range includes crimp terminals, wire terminals, D-Sub connectors, wiring harness components, and OEM/ODM interconnect solutions for industrial, automotive, medical, and energy applications.

Yes. OEM and ODM projects are a core part of our business. We support custom designs based on drawings, samples, or performance requirements, including material selection, tooling development, electrical validation, and mass production.

Our manufacturing system complies with international quality and environmental standards, including ISO 9001, ISO 14001, ISO 13485, IATF 16949, IPC/WHMA-A-620, and selected products meet UL requirements. Strict in-process inspection and final testing ensure consistent product quality.

We control quality through the entire manufacturing process, including precision stamping, automated crimping, electroplating, injection molding, and assembly. Statistical process control (SPC), dimensional inspections, and electrical performance testing are applied to ensure batch-to-batch consistency.

Our products are widely used in industrial automation, automotive and EV systems, medical devices, power generation, consumer electronics, and telecommunications. We support both high-volume production and low-to-medium volume customized projects.

Yes. Qianwei Precision has extensive experience serving global OEMs and distributors. We support international logistics, export documentation, and English-language technical and commercial communication to ensure smooth cooperation.

Absolutely. Our engineering team assists customers with connector selection, crimp validation, material recommendations, drawings, and application analysis, helping reduce design risks and improve overall system performance.

Customers choose Qianwei Precision for our manufacturing expertise, consistent quality, strong engineering support, and responsive service. We focus on building long-term partnerships rather than short-term transactions.

What's New?

Algerian Customer Visits Qianwei to Explore Motorcycle Wire Harness Cooperation and Future Automotive Projects

-

Posted by

Qianwei Precision

- 0 comments

German Connector Company Visits Qianwei Precision and Establishes Strategic Agency Partnership

-

Posted by

Qianwei Precision

- 0 comments

Eberspaecher Representatives Visits Qianwei Precision to Discuss Automotive Air Conditioning Wiring Harness Project

-

Posted by

Qianwei Precision

- 0 comments

Happy 2026

-

Posted by

Qianwei Precision

- 0 comments