As OEM equipment becomes more advanced, electrical systems face increasing demands for signal integrity, noise control, and long-term reliability. In high-density and high-vibration environments, cable performance is no longer just a component-level concern—it directly impacts system uptime, safety, and lifecycle cost.

Wire twisting is a proven engineering solution that helps OEMs meet these challenges. As a core process in custom cable assembly, it improves electrical stability, mechanical durability, and installation consistency across demanding industrial applications.

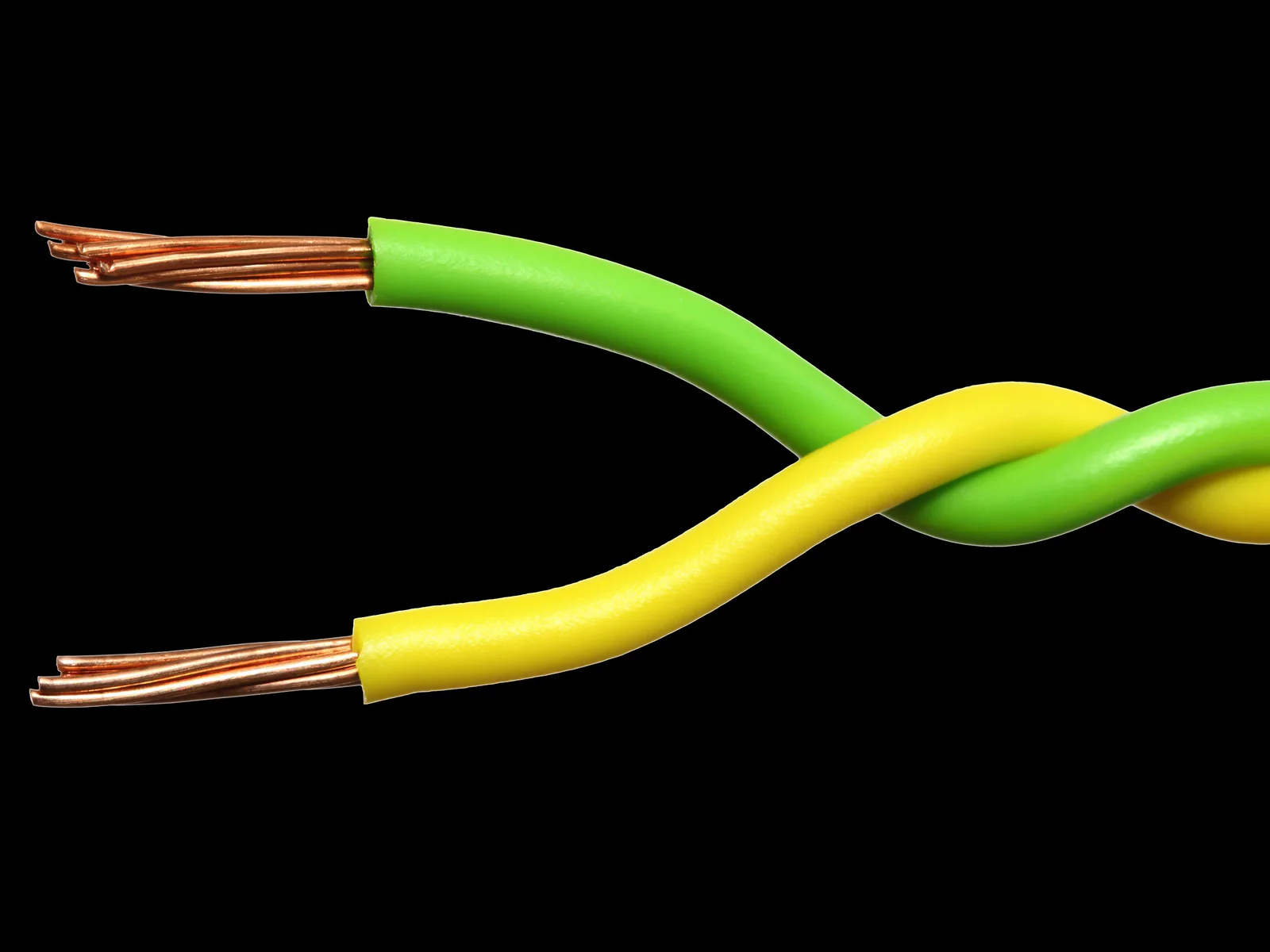

What Is Wire Twisting?

Wire twisting is the controlled process of winding two or more conductors together in a uniform spiral pattern. This technique has been used for decades to reduce electrical interference and stabilize signal transmission.

In modern OEM cable assemblies, wire twisting ensures consistent conductor spacing and balanced geometry. These characteristics are essential for minimizing electromagnetic interference (EMI), reducing crosstalk, and maintaining predictable electrical performance in complex systems.

Rather than being a secondary manufacturing step, wire twisting is an intentional design choice that directly influences reliability, flexibility, and system performance.

Why Wire Twisting Matters for OEM Applications

OEMs operating in transportation, industrial automation, energy, and heavy equipment environments demand repeatable performance from every electrical connection. Wire twisting supports those requirements by improving both electrical and mechanical stability.

In real-world operating conditions—where vibration, motion, heat, and electrical noise are common—untwisted or poorly structured wiring can lead to intermittent signals, premature wear, and costly downtime. Twisted wire assemblies provide structure, consistency, and long-term resilience, helping OEMs reduce field failures and maintenance risk.

Electrical Performance Benefits of Twisted Wire Assemblies

Improved Signal Integrity

Uniform twisting maintains consistent impedance along the cable length. This reduces signal distortion and supports reliable data and power transmission, even in tightly packed or noise-sensitive environments.

Reduced EMI and Crosstalk

By balancing electromagnetic fields between conductors, wire twisting significantly lowers susceptibility to external interference and prevents signal leakage between adjacent wires. This is critical for sensors, control circuits, and communication lines in dense electrical systems.

Stable Performance in High-Density Systems

In compact harness designs, twisted wire configurations help maintain predictable electrical behavior, supporting system accuracy and operational consistency.

Mechanical Advantages for Demanding Environments

Enhanced Durability

Twisted wire structures distribute mechanical stress evenly across conductors. This reduces localized strain, minimizes wear, and extends service life in applications exposed to vibration or repeated movement.

Improved Flexibility and Routing

Controlled twist patterns help cables bend more naturally, reducing kinks and installation damage. This improves routing efficiency and protects conductors during assembly and operation.

OEM Applications That Rely on Wire Twisting

Automotive and Heavy Equipment

Wire twisting is widely used in powertrain systems, sensors, lighting, and control harnesses. It supports reliable performance under constant vibration, temperature fluctuations, and mechanical stress.

Industrial Automation and Machinery

In control cabinets, robotic systems, and industrial equipment, twisted wire assemblies help maintain signal clarity amid dense wiring and electromagnetic noise.

Specialized Vehicles and Harsh-Environment Equipment

Applications such as generators, marine engines, off-road vehicles, and emergency equipment depend on twisted wire harnesses to maintain electrical stability in extreme operating conditions.

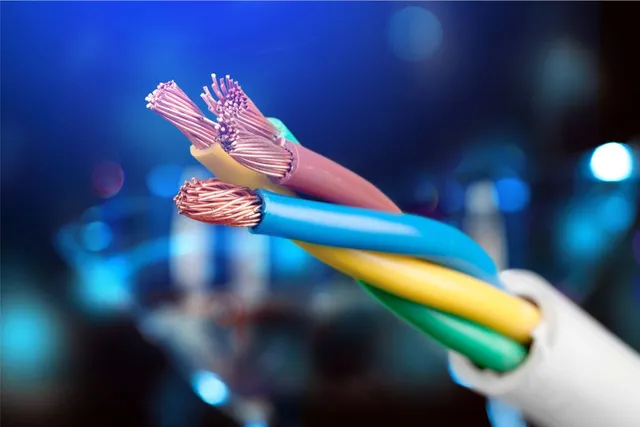

Choosing the Right Wire Twisting Configuration

Wire twisting performance depends on multiple engineering variables, including twist pitch, conductor material, insulation type, and overall harness layout.

-

Tighter twist pitches improve noise rejection but increase stiffness

-

Looser twists enhance flexibility but may allow higher EMI exposure

The optimal configuration is always application-specific. OEMs benefit from working with a manufacturing partner who understands these tradeoffs and designs wire twisting into the assembly from the earliest engineering stages.

Engineering Wire Twisting for OEM Reliability

At Kato Cable, wire twisting is an integrated part of our cable assembly design process—not an afterthought. Our engineering team evaluates how each harness will be installed, routed, and operated in the field.

We work closely with OEM customers to:

-

Optimize twist pitch for EMI reduction and flexibility

-

Select conductor and insulation materials based on operating conditions

-

Ensure consistency through automated processing and in-process inspection

The result is a wire twisting solution engineered for real-world performance, not just laboratory specifications.

Your Partner for High-Reliability Cable Assemblies

In OEM systems, electrical reliability starts with disciplined engineering and proven manufacturing processes. Wire twisting plays a critical role in delivering stable, durable, and repeatable performance across industries.

By partnering with an experienced cable assembly manufacturer, OEMs gain more than a finished product—they gain confidence in long-term system reliability.

Contact Qianwei Pecision today to discuss your wire twisting and custom cable assembly requirements.

FAQs About Wire Twisting in OEM Cable Assemblies

Does wire twisting affect cable current-carrying capacity?

Wire twisting itself does not significantly reduce current-carrying capacity when properly engineered. However, factors such as conductor gauge, insulation material, twist pitch, and thermal environment must be considered together to ensure the cable meets electrical and temperature requirements.

Is wire twisting required for all cable assemblies?

Not all cable assemblies require wire twisting. It is most beneficial in applications involving signal transmission, EMI-sensitive circuits, vibration, or dense routing. Straight or bundled wires may be sufficient for simple, low-noise, static applications.

How is twist pitch determined for a specific application?

Twist pitch is selected based on EMI requirements, signal type, flexibility needs, and mechanical stress. Tighter twists improve noise rejection, while looser twists increase flexibility. OEM applications typically require application-specific testing or engineering validation to determine the optimal balance.

Can wire twisting improve long-term reliability in high-vibration environments?

Yes. Twisted wire configurations distribute mechanical stress more evenly across conductors, reducing fatigue caused by vibration and movement. This helps prevent conductor breakage, insulation wear, and intermittent electrical failures over time.

How does wire twisting impact cable assembly cost?

While wire twisting adds a controlled processing step, it often reduces total system cost by improving reliability, simplifying routing, and minimizing field failures. For OEMs, the long-term benefits in performance and durability typically outweigh the incremental manufacturing cost.