Connector in rail solution

Connectors in rail solutions are designed to ensure reliable electrical and signal connections in demanding railway environments. They are built to withstand vibration, shock, temperature extremes, and moisture, ensuring safe and stable operation of systems such as power supply, communication, control, and lighting throughout trains and rail infrastructure.

Overview

Qianwei’s rail solution connectors are engineered to deliver stable and reliable performance in the demanding environments of railway systems. Designed to resist vibration, shock, high temperatures, and moisture, these connectors ensure consistent power and signal transmission for critical rail applications.

They are widely used in train control systems, communication networks, lighting, and power distribution. With high durability and safety standards, Qianwei’s rail connectors provide long-lasting performance and help enhance the efficiency and reliability of modern rail transportation systems.

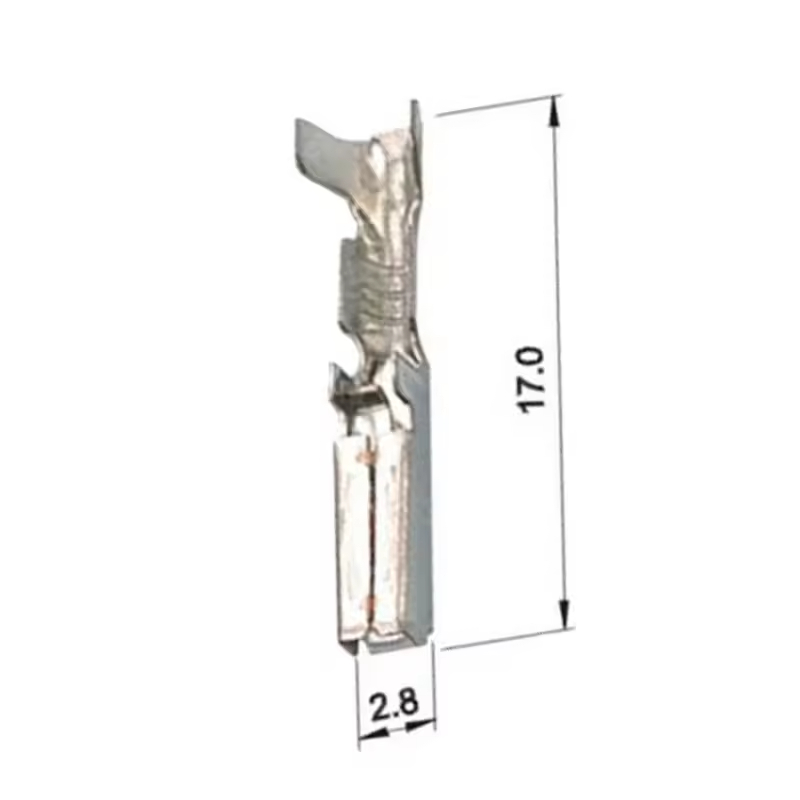

Products

FAQ

Railway systems operate under continuous vibration, temperature variation, and long service life requirements. Qianwei Precision designs rail-grade terminals and connectors to ensure stable electrical contact, strong mechanical retention, and consistent performance over extended operating cycles, helping reduce maintenance and system downtime.

Yes. We offer custom design and manufacturing services based on customer drawings, technical specifications, and project requirements. Our engineering team works closely with rail equipment manufacturers and system integrators to develop components optimized for vibration resistance, space constraints, and installation efficiency.

We implement strict quality control processes, including incoming material inspection, process monitoring, dimensional measurement, and functional testing. Full documentation and traceability are maintained to support long-term rail project requirements.

Yes. Rail transit projects typically require long product lifecycles and stable spare part availability. Qianwei Precision supports long-term production planning, tooling management, and controlled design changes to ensure consistent supply throughout the operational life of rail systems.

We provide comprehensive engineering support, including technical drawings, material specifications, process documentation, and quality records. Upon request, we can assist with sample validation, testing coordination, and documentation preparation to support rail project approval and system integration.

Contact

Thank you for your interest. We are here to help!