In electrical systems and wire harness assemblies, wire termination is just as critical as the wire or cable itself. Poor termination choices can lead to signal loss, overheating, mechanical failure, or long-term reliability issues. Among the most common design decisions engineers and buyers face is whether to use single-wire termination or multi-wire termination.

This article provides a detailed explanation of single-wire vs. multi-wire termination, including their structures, advantages, limitations, typical applications, and selection guidelines. Understanding these differences will help you design safer, more reliable electrical systems and choose the right termination solution for your application.

Understanding Wire Termination

Wire termination refers to the method used to connect one or more conductors to a terminal, connector, or contact point. Termination methods typically involve crimping, soldering, welding, or insulation displacement, and they directly affect electrical performance, mechanical strength, and long-term durability.

From a functional perspective, wire termination can be divided into two main categories:

Single-wire termination

Multi-wire termination

Each serves a different purpose and is optimized for different electrical and mechanical requirements.

What Is Single-Wire Termination?

Definition

Single-wire termination is a termination method where one conductor is connected to one terminal or contact point. The conductor may be solid or stranded and is typically terminated using crimp terminals, solder lugs, or insulation displacement contacts (IDC).

Common Structures

One wire → one terminal

Solid or stranded conductor

Insulated or bare conductor end

Crimped, soldered, or IDC connection

Typical Terminals Used

Ring terminals

Spade (fork) terminals

Blade terminals

Pin terminals

Ferrules

Advantages of Single-Wire Termination

High Reliability and Stability

Single-wire termination provides a direct and stable electrical path, minimizing contact resistance and reducing the risk of overheating.

Easier Quality Control

Because only one conductor is involved, it is easier to:

Verify crimp quality

Control pull-out force

Maintain consistent electrical performance

Better for High-Current Applications

Single-wire terminations are commonly used in power circuits where current load, heat dissipation, and safety are critical.

Simple Installation and Maintenance

Faster assembly

Easier troubleshooting

Lower risk of wiring errors

Limitations of Single-Wire Termination

Requires more terminals and connection points in complex systems

Increases wiring density in large harnesses

Less efficient for multi-signal transmission

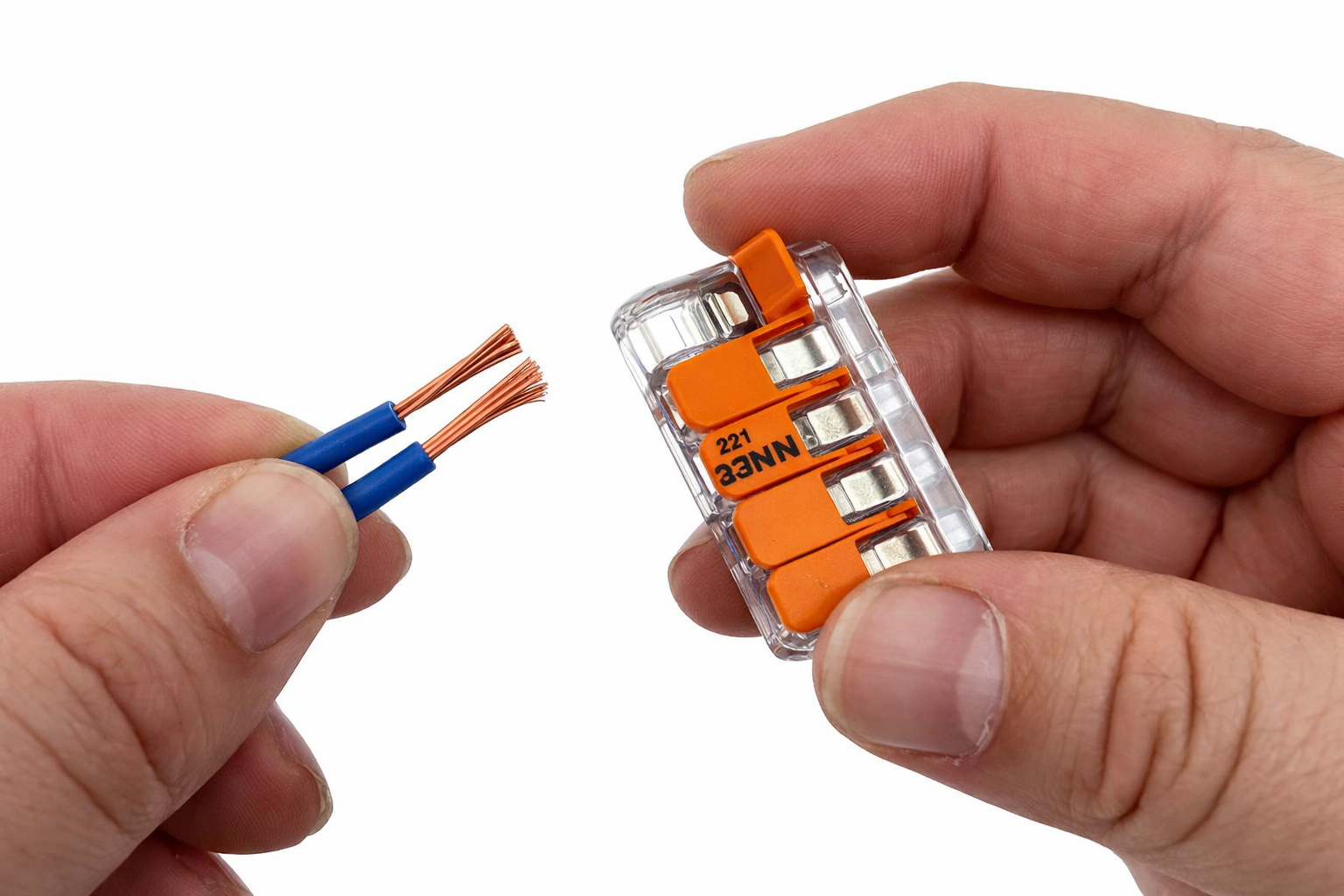

What Is Multi-Wire Termination?

Definition

Multi-wire termination is a method where two or more wires are terminated into a single terminal or contact point. This approach is often used to simplify wiring, save space, or combine multiple signals or grounds.

Common Structures

Multiple conductors → one terminal

Wires may be twisted or parallel

Often used in grounding or signal grouping

Typical Terminals Used

Multi-wire crimp terminals

Closed-barrel terminals

Splice terminals

IDC connectors

Specialized OEM terminals

Advantages of Multi-Wire Termination

Space and Weight Reduction

By combining multiple wires into one termination point, multi-wire termination:

Reduces connector size

Lowers overall harness weight

Simplifies routing in compact designs

Efficient for Grounding and Signal Grouping

Commonly used for:

Ground connections

Common power distribution

Signal reference lines

Reduced Assembly Time

Fewer terminals and contact points can lead to:

Faster harness assembly

Lower material costs in high-volume production

Limitations of Multi-Wire Termination

Higher Risk of Inconsistent Crimp Quality

Ensuring equal compression on multiple conductors is more challenging, especially when wire sizes differ.

More Difficult Inspection and Rework

Harder to visually inspect

Re-termination may require replacing the entire terminal

Not Ideal for High-Current Loads

Uneven current distribution can lead to localized heating and long-term reliability issues.

Single-Wire vs. Multi-Wire Termination: Key Differences

| Aspect | Single-Wire Termination | Multi-Wire Termination |

| Number of conductors | One wire per terminal | Two or more wires per terminal |

| Electrical stability | Very high | Moderate |

| Current handling | Excellent | Limited |

| Assembly complexity | Low | Medium to high |

| Space efficiency | Lower | Higher |

| Maintenance | Easy | More difficult |

| Typical use | Power, safety-critical circuits | Grounding, signal grouping |

Typical Application Scenarios

When to Choose Single-Wire Termination

High-current circuits

Safety-critical systems

Automotive power distribution

Industrial equipment

Battery and energy storage systems

When to Choose Multi-Wire Termination

Ground circuits

Signal return lines

Compact control panels

Consumer electronics

Data and communication systems

Termination Methods Used for Both Types

Regardless of single-wire or multi-wire termination, common termination processes include:

Crimp termination – Most widely used in automotive and industrial harnesses

Solder termination – Used where vibration is minimal

IDC termination – Common in data and communication connectors

Ultrasonic welding – High-reliability OEM applications

The choice of method depends on current rating, vibration, environment, and production volume.

UL Standards and Compliance Considerations

Termination quality is often regulated by UL and industry standards, especially for North American markets.

Common UL References

UL486A-486B (wire connectors)

UL310 (crimp terminals)

UL817 (cord sets)

UL508A (industrial control panels)

Compliance ensures:

Electrical safety

Mechanical reliability

Regulatory acceptance

How to Choose the Right Termination Solution

When selecting between single-wire and multi-wire termination, consider the following factors:

Current and voltage requirements

Number of signals

Space and layout constraints

Environmental conditions (vibration, temperature, moisture)

Assembly volume and cost

Inspection and maintenance needs

In many wire harness designs, both termination types are used together, each applied where it performs best.

Why Termination Design Matters for Long-Term Reliability

Termination failures are one of the most common causes of electrical system breakdowns. Choosing the correct termination method:

Reduces warranty risks

Improves system lifespan

Enhances electrical safety

Lowers total cost of ownership

For OEMs and system integrators, termination design is not just a technical detail—it is a critical reliability decision.

Looking for Custom Wire Termination Solutions?

If you need custom terminals, wire harness assemblies, or OEM termination solutions, working with an experienced manufacturer ensures proper design, material selection, and compliance with industry standards.

Contact Qianwei Precision-a professional wire harness supplier to discuss your project requirements and receive technical support from design to mass production.

FAQs

1. Can single-wire and multi-wire terminations be used in the same wire harness?

Yes. In most professional wire harness designs, single-wire and multi-wire terminations are used together. Single-wire termination is typically applied to power and safety-critical circuits, while multi-wire termination is used for grounding or signal grouping where appropriate.

2. Is multi-wire termination acceptable for automotive applications?

Multi-wire termination is acceptable in automotive systems when used correctly, such as for ground connections or low-current signal circuits. However, high-current or safety-related circuits usually require single-wire termination to ensure consistent electrical performance and long-term reliability.

3. How does wire gauge affect multi-wire termination quality?

Wire gauge consistency is critical in multi-wire termination. Mixing different wire sizes in one terminal can lead to uneven crimp compression, increased contact resistance, and reduced pull-out strength. For best results, wires in a multi-wire termination should be the same or very similar gauge.

4. Which termination method works best with multi-wire terminations?

Crimp termination and ultrasonic welding are the most common and reliable methods for multi-wire termination. Soldering is generally not recommended for multi-wire terminations in vibration-prone environments due to the risk of fatigue and cracking.

5. Does multi-wire termination reduce material cost?

Multi-wire termination can reduce material cost by decreasing the number of terminals and connector cavities required. However, this must be balanced against higher process control requirements and potential inspection challenges.

6. Are there specific terminals designed for multi-wire termination?

Yes. Some terminals are specifically engineered for multi-wire termination, featuring wider barrels, controlled crimp zones, or closed-barrel designs. Using standard single-wire terminals for multi-wire termination is not recommended unless approved by the terminal manufacturer.

7. How do I ensure quality control for multi-wire terminations?

Quality control typically includes pull-force testing, cross-section analysis, visual inspection, and crimp height measurement. Because defects are harder to detect visually, multi-wire terminations often require stricter process validation.

8. When should I avoid multi-wire termination entirely?

Multi-wire termination should be avoided in high-current circuits, safety-critical systems, or applications exposed to extreme vibration and thermal cycling. In these cases, single-wire termination provides better electrical stability and long-term durability.