Ribbon cable assemblies are widely used in modern electronic systems where saving space, keeping wiring organized, and connecting multiple conductors reliably are important. Also known as flat ribbon cable assemblies or planar cable assemblies, they are commonly found in computers, industrial automation systems, medical devices, and consumer electronics.

In this guide, we’ll walk through the basics of ribbon cable assemblies—how they are built, their key specifications, main advantages, and common applications—to help engineers and buyers choose the right solution for their specific needs.

What Is a Ribbon Cable Assembly?

A ribbon cable assembly consists of multiple insulated conductors arranged in a flat, parallel configuration and terminated with connectors—most commonly IDC (Insulation Displacement Connectors). Unlike round cables where conductors are bundled together, ribbon cables maintain a fixed spacing between each wire, creating a flat, ribbon-like profile.

This design allows multiple signals to be transmitted simultaneously in an organized manner, reducing cable clutter and simplifying installation in space-constrained environments.

Structural Characteristics and Design Features

The defining feature of a ribbon cable is its flat and wide geometry. Conductors are laid side by side in a single plane, which provides several practical benefits:

- Efficient routing in tight or shallow spaces

- Consistent conductor spacing, ensuring reliable connector alignment

- Improved cable management compared to round multi-core cables

Ribbon cables are flexible along their length but have limited lateral flexibility. They are best suited for straight runs. When a change in direction is required, installers typically fold the cable over itself to achieve a right-angle transition without stressing the conductors.

Common Ribbon Cable Specifications

Ribbon cable assemblies are generally defined by two primary parameters: conductor spacing (pitch) and number of conductors. Additional considerations include wire gauge and insulation material.

Conductor Spacing (Pitch)

Pitch refers to the center-to-center distance between adjacent conductors. Standard pitch options include:

- 0.025 inch

- 0.050 inch

- 0.100 inch

- 0.156 inch

- 1.0 mm

Custom pitches are also available for specialized applications or proprietary connector systems.

Number of Conductors

The number of conductors—also known as “ways” or “positions”—corresponds directly to the connector’s pin count. Because IDC connectors are standardized, ribbon cable assemblies are typically produced in common configurations such as:

4, 6, 8, 9, 10, 14, 15, 16, 18, 20, 24, 25, 26, 34, 37, 40, 50, 60, 64, and 80 conductors.

This standardization ensures compatibility with a wide range of connectors and simplifies system design.

Wire Gauge and Insulation Materials

Most ribbon cable assemblies use stranded copper conductors, offering flexibility and durability. Typical wire sizes range from 18 AWG to 34 AWG, with finer gauges available for low-current or signal-level applications.

Common insulation materials include:

- PVC – cost-effective and widely used

- PTFE (Teflon) – suitable for high-temperature environments

- Olefin-based materials – offering improved chemical resistance

Material selection depends on operating temperature, environmental exposure, and regulatory requirements.

Cable Identification and Orientation

Proper conductor identification is essential to prevent misalignment and reversed connections during assembly and installation.

Edge-Marked Ribbon Cables

Many ribbon cables feature a single conductor marked with a contrasting color along one edge of the cable. This edge marking identifies Pin 1 and ensures correct connector orientation. In some cases, the color of the edge mark corresponds to the pitch of the cable—for example, red edge markings are commonly associated with 0.050-inch pitch ribbon cables.

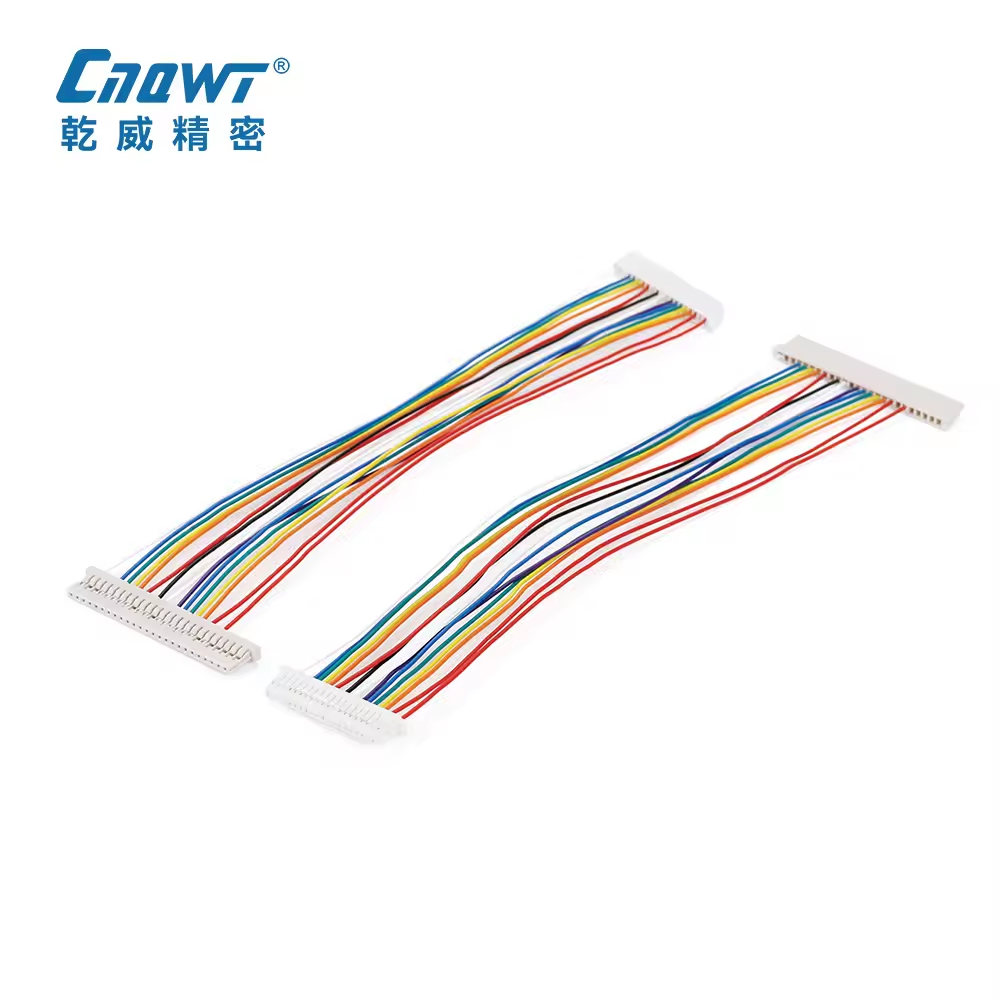

Color-Coded Ribbon Cables

Color-coded or “rainbow” ribbon cables use individually colored conductors arranged in a repeating pattern. The sequence typically follows the standard resistor color code:

Brown, Red, Orange, Yellow, Green, Blue, Violet, Gray, White, Black

For assemblies with more than ten conductors, the color pattern repeats. This design makes conductor identification easier during troubleshooting, modification, or partial termination.

Key Advantages of Ribbon Cable Assemblies

One of the most significant advantages of ribbon cable assemblies is termination efficiency. Because conductor spacing is fixed and controlled, ribbon cables can be mass-terminated using IDC connectors.

IDC Termination Benefits

IDC connectors use fork-shaped contacts that pierce the insulation and make direct contact with the conductor, eliminating the need for stripping individual wires. This method provides:

- Faster assembly time

- Consistent electrical performance

- Reduced labor costs

- Improved repeatability in high-volume production

Assemblies may be terminated with IDC connectors on both ends, or configured with mixed terminations such as IDC on one end and crimped or soldered contacts on the other.

Understanding IDC Connectors

IDC connectors are defined by several key parameters:

- Pin spacing (pitch)

- Number of pins

- Number of rows (single-row or dual-row)

Ribbon cables and IDC connectors are designed to work as a matched system, ensuring precise alignment and reliable electrical contact across all conductors.

Typical Applications of Ribbon Cable Assemblies

Ribbon cable assemblies are widely used in applications that require organized multi-signal transmission in confined spaces, including:

- Computer and data storage equipment (hard drives, optical drives)

- Consumer electronics and household appliances

- Printers and print head connections

- Test and measurement instruments

- Industrial automation and robotic systems

- Medical devices and diagnostic equipment

Their flat profile and standardized configurations make them particularly suitable for internal wiring and board-to-board or board-to-device connections.

Design Considerations and Selection Tips

When selecting a ribbon cable assembly, engineers should evaluate:

- Available installation space

- Required conductor count and pitch

- Electrical performance requirements

- Environmental conditions such as temperature, vibration, and chemical exposure

- Compatibility with existing connectors

For high-temperature or harsh environments, alternative insulation materials should be considered to ensure long-term reliability.

Conclusion

Ribbon cable assemblies offer a practical, space-saving, and cost-effective solution for applications requiring multiple parallel connections. With standardized pitches, conductor counts, and IDC compatibility, they simplify system design while supporting efficient mass termination.

Whether used in industrial machinery, electronics, or medical equipment, ribbon cable assemblies remain a reliable choice when compact layout and organized wiring are essential.

FAQ

1. What are ribbon cable assemblies commonly used for?

Ribbon cable assemblies are commonly used in applications that require multiple signal connections in a compact and organized layout. Typical uses include computers, industrial control systems, medical equipment, test instruments, and consumer electronics, where space-saving and consistent wiring are important.

2. What connectors are typically used with ribbon cables?

The most common connectors used with ribbon cable assemblies are IDC (Insulation Displacement Connectors), such as IDC sockets, box headers, and edge connectors. These connectors allow for fast, reliable termination without stripping individual wires.

3. How do I choose the right pitch for a ribbon cable assembly?

Ribbon cable pitch is usually selected based on connector compatibility and signal density requirements. Common pitches include 1.27 mm (0.050″) and 2.54 mm (0.100″). Smaller pitches are used for high-density applications, while larger pitches are preferred for easier handling and robustness.

4. Are ribbon cable assemblies suitable for high-speed or sensitive signals?

Ribbon cable assemblies can be used for moderate-speed digital signals, but for high-speed or noise-sensitive applications, design considerations such as grounding conductors, controlled impedance, and shielding may be required. In some cases, alternative cable types may be recommended.

5. Can ribbon cable assemblies be customized?

Yes. Ribbon cable assemblies can be fully customized in terms of cable length, conductor count, pitch, connector type, orientation, and labeling. Custom assemblies help ensure proper fit, reliable performance, and easier installation in specific systems.