Electrical terminals is extremely important in electrical and electronic systems. They are the connection points that allow electricity to flow safely and reliably between wires, components, and devices. Without properly functioning terminals, even the most advanced electrical system can suffer from power loss, overheating, or failure.

In simple terms, electrical terminals work by creating a secure mechanical and electrical connection between conductors, ensuring stable current flow, low contact resistance, and long-term reliability under mechanical and environmental stress.

How Electrical Terminals Function

Electrical terminals work through a straightforward but highly engineered process:

The wire insulation is stripped to expose the conductor

The conductor is inserted into or placed onto the terminal

Mechanical force is applied (crimping, tightening, or spring pressure)

Metal-to-metal contact is established

The connection maintains conductivity over time, even under vibration or heat

This combination of mechanical retention and electrical contact is what makes terminals indispensable in wiring systems.

The Basic Working Principle of Electrical Terminals

At their core, electrical terminals rely on two fundamental principles: mechanical connection and electrical conductivity.

Mechanical Connection

The mechanical function of a terminal is to hold the conductor firmly in place. Depending on the terminal type, this is achieved by:

Crimping force that compresses metal around the wire

Screw torque that clamps the conductor

Spring tension that maintains constant pressure

A stable mechanical connection prevents wire pull-out, loosening, and vibration-related failures.

Electrical Contact and Conductivity

Once the conductor is secured, the terminal must ensure efficient current flow. This requires:

Large contact surface area

Low contact resistance

Clean metal-to-metal contact

To enhance conductivity and prevent oxidation, terminals are often plated with materials such as tin, nickel, or silver.

Step-by-Step: How an Electrical Terminal Makes a Reliable Connection

Step 1 – Wire Preparation

The insulation is stripped to the correct length, exposing the conductor without damaging the strands. Proper stripping is essential to avoid weak connections.

Step 2 – Terminal Insertion or Positioning

The conductor is inserted into the terminal barrel, placed under a screw clamp, or aligned with a spring mechanism, depending on the terminal design.

Step 3 – Connection Method Applied

Different terminals use different methods to secure the wire:

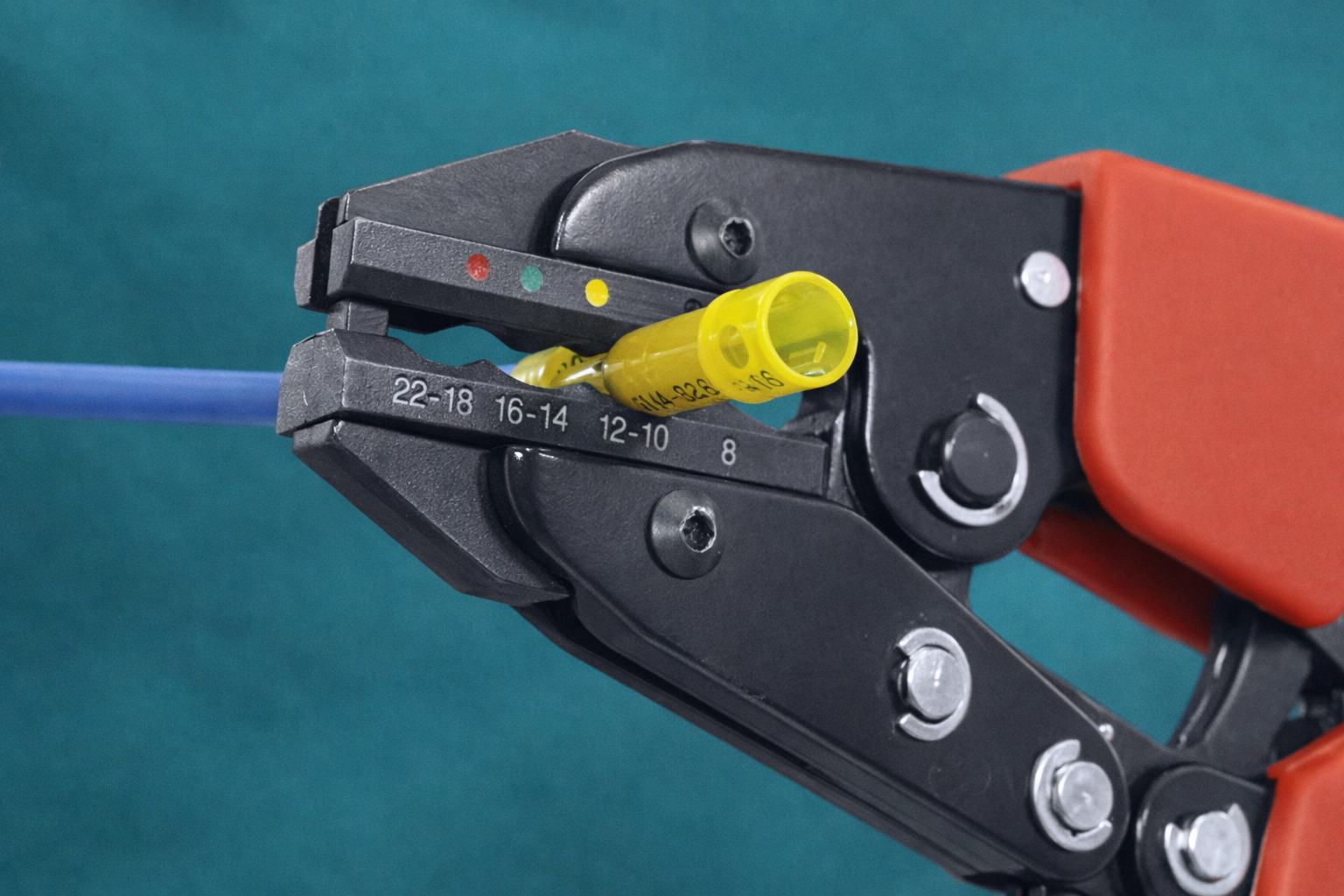

Crimping compresses the terminal barrel around the conductor

Screws apply controlled clamping force

Spring terminals use elastic force to maintain constant pressure

Step 4 – Long-Term Stability

A correctly made terminal connection resists:

Vibration

Thermal expansion and contraction

Corrosion

Mechanical stress

This stability is critical for long service life.

How Different Types of Electrical Terminals Work

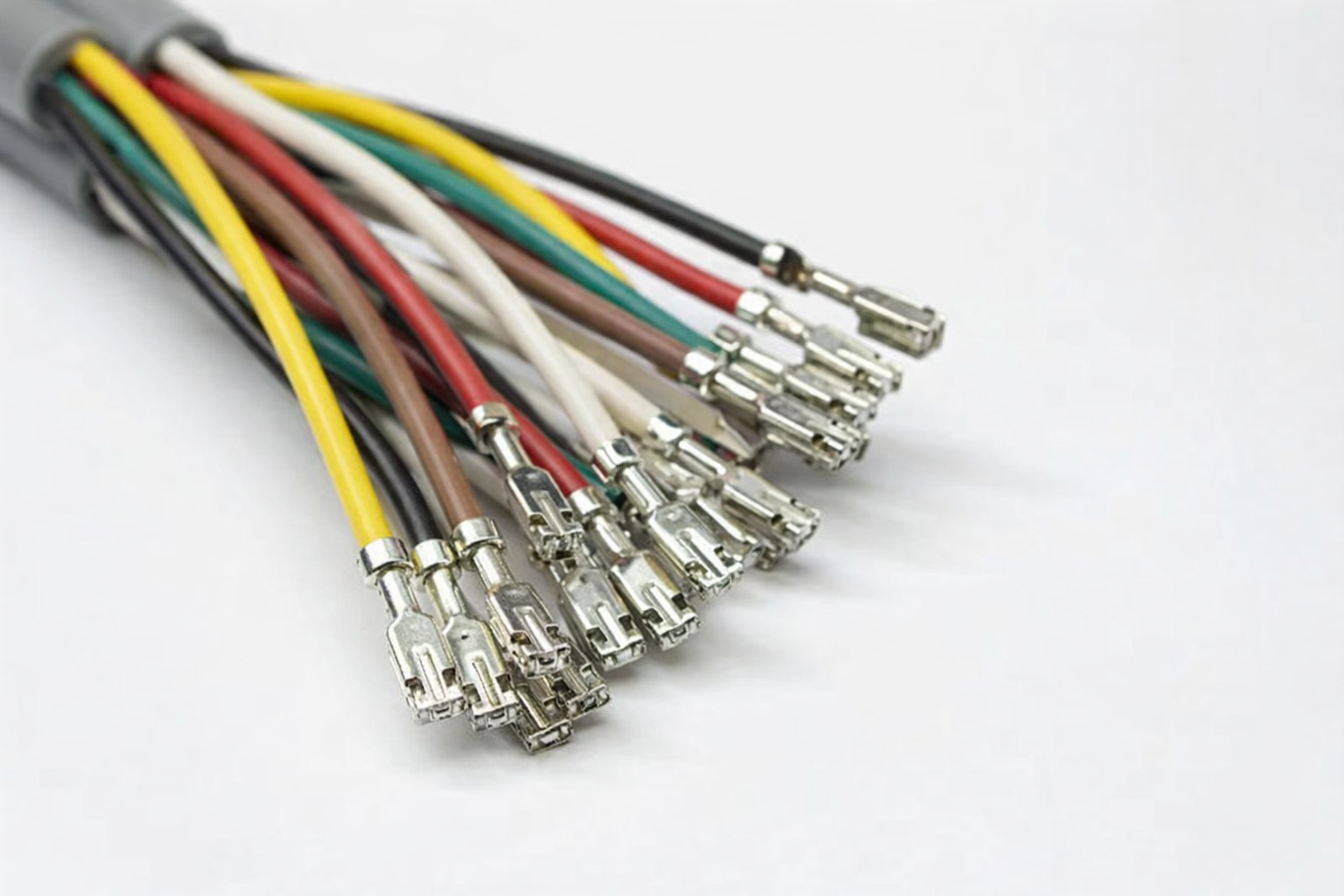

Crimp Terminals

Crimp terminals work by permanently deforming the metal barrel around the conductor using a calibrated crimping tool. This creates a gas-tight connection, preventing oxidation and ensuring very low resistance.

They are widely used in automotive wiring harnesses and industrial equipment.

Screw Terminals

Screw terminals work by tightening a screw that clamps the conductor against a conductive surface. Proper torque is essential to prevent loosening or wire damage.

These terminals are common in control panels and power distribution systems.

Ring and Spade Terminals

Ring and spade terminals are attached to wires (usually by crimping) and then fastened to studs or screws. The ring shape prevents accidental disconnection, making them ideal for high-vibration environments.

Spring / Push-In Terminals

Spring terminals use internal spring force to press the conductor against a contact surface. They provide fast installation and consistent pressure without tools.

Where and Why Electrical Terminals Are Used

Electrical terminals are used wherever safe and reliable connections are required, including:

Automotive wiring harnesses

Industrial control cabinets

Power distribution systems

Home appliances and consumer electronics

They allow systems to be assembled, serviced, and repaired efficiently without soldering or permanent joints.

Key Factors That Affect Terminal Performance

Several factors determine how well an electrical terminal works:

Wire size and material compatibility

Correct crimp force or tightening torque

Terminal plating and corrosion resistance

Operating temperature range

Exposure to vibration and mechanical stress

Ignoring these factors can lead to overheating, voltage drop, or connection failure.

FAQs

How do electrical terminals ensure low resistance?

By creating firm metal-to-metal contact with sufficient contact pressure and proper surface plating.

What happens if a terminal is improperly crimped?

Poor crimping can cause high resistance, overheating, or wire pull-out.

Are crimp terminals better than soldering?

In many industrial applications, yes. Crimping provides better vibration resistance and avoids solder fatigue.

How long do electrical terminals last?

When properly selected and installed, terminals can last decades.

Can electrical terminals handle vibration?

Yes, especially crimp and ring terminals designed for automotive and industrial use.

Do terminals require maintenance?

Generally no, but screw terminals may need periodic inspection in high-vibration environments.

Summary: How Electrical Terminals Work

Electrical terminals work by combining mechanical retention and electrical conductivity to create safe, reliable connections. Through proper design, material selection, and installation, terminals ensure stable current flow across a wide range of applications. Choosing the right terminal type and applying it correctly is essential for system performance and long-term reliability. Contact us for more information.